* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

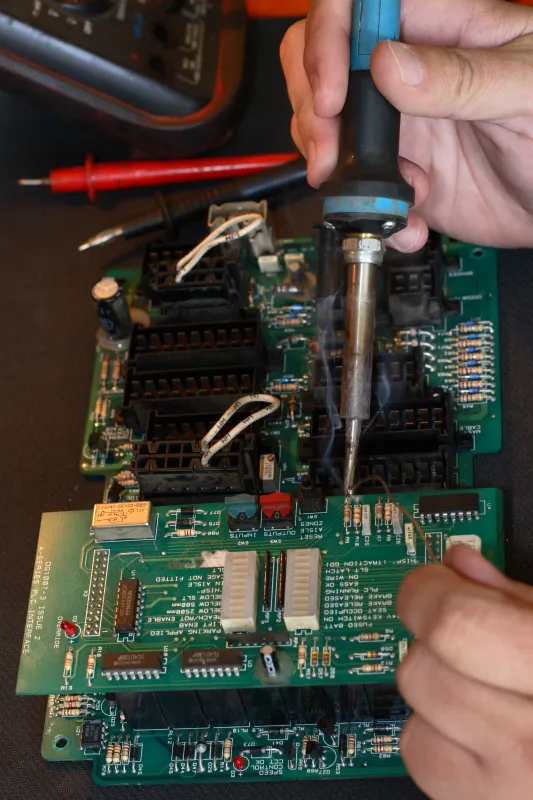

Any electronic gadget with a circuit board would require soldering to join the components together if you were to disassemble it. Melting solder around a connector to unite two or more electronic components is called soldering. Solder is a metal alloy that forges a robust electrical connection between components as it cools. Even though soldering can provide a permanent connection, it can also be undone by following the instructions below for a desoldering tool.

Tin and lead are mixed in varying ratios to create the metal alloy that is used as solder in electronics. These ratios are typically indicated on the many kinds of solder that are readily available.

The majority of tin/lead solder mixtures do not melt at the same time. At 183 C, or 361 F, fifty-fifty solder starts to melt, but it doesn't completely melt until it hits 216 C, or 420 F. The solder is semi-liquid or plastic between these two temperatures.

A solder's plastic range is influenced by the tin to lead ratio. The range is somewhat less with 60/40 solder than it is with 50/50 solder. Eutectic solder, or 63/37 ratio, melts nearly instantly at 183 C -361 F and has almost little plastic range.

The 60/40 and 63/37 types of solders are most frequently used for hand soldering in electronics. You must take care throughout the cool-down period to avoid moving any joint elements because of the 60/40 type's plastic range. Something called a disturbed joint can result from movement. A disrupted joint appears dull rather than glossy and has a rough, uneven aspect. Rework may be necessary if the solder joint is disrupted as it may be unreliable.

Soldering can be classified into the following three categories: fusion welding, pressure welding and brazing.

Besides, soldering has other categories such as ultrasonic pressure welding, gold ball bonding and laser soldering.

Brazing can be also classified into hard brazing and soft brazing. The former refers to high temperature and large scale soldering while the latter refers to relatively low temperature and small scale soldering such as component soldering. Concerning some aspects on soft brazing, the following content is complemented.

a. Definition: Soft brazing refers to the soldering with a temperature that is lower than 450°C.

b. Features: The following figure indicates features of soft brazing.

c. Basic theory

When metal is being soldered and the soldered metal is heated to the certain temperature range, the oxide layer and contaminant will be cleaned under the activation of welding flux and metal surface will obtain sufficient activation energy. Melting solder is melted, wetted, expanded and connected with metallurgy. As weld occurs between solder and soldered metal surface, solder will become solid after cooling with soldering points formed. Strength of extension is related with lattice structure and thickness of bonding layer between metal.

d. Brazing procedure: The main procedure of soft brazing includes wetting, diffusion, dissolution and metallurgic bonding.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108