* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

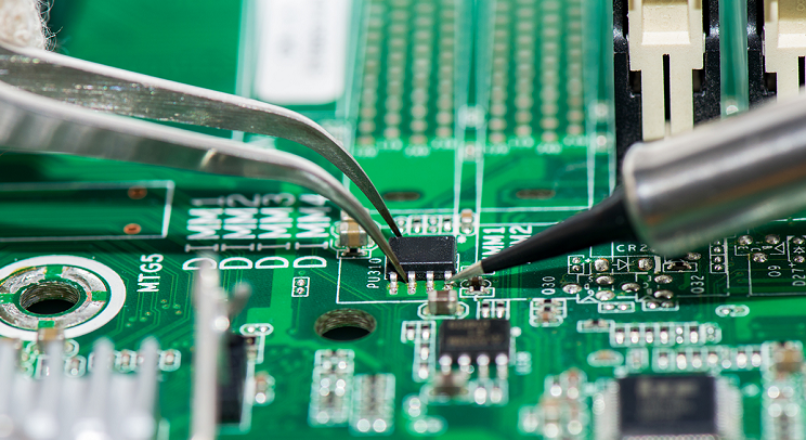

Before starting work on the PCB bare board, it's important to first check for any short circuits, circuit breaks or other problems. It's also useful to have a look at the development board schematic diagram and compare it with the PCB screen printing layer to avoid any discrepancies.

Once you have all the materials required for the reflow oven, it's best to classify the components according to their sizes for easier welding. Make sure to print a complete material list. During the welding process, cross out the corresponding options with a pen if welding is not yet completed. This will help in facilitating the subsequent welding operation.

1. Warehouse management personnel should wear anti-static gloves during the process of distributing materials and IQC testing, the meter should be grounded, and the work surface should be covered with anti-static rubber pads.

2. In the specific production process, an anti-static work surface is required, and the components and semi-finished products are placed in an anti-static container. The welding equipment must be reliably grounded, and the electric soldering iron must be of anti-static type. All equipment must be tested before being used and qualified.

3. In the process of PCBA processing, the tin flow will have an impact on the pins of the plug-in. Some plug-ins may be tilted after being welded by the furnace, which will cause the component body to exceed the range of the silk screen frame, so the repair welding personnel after the tin furnace This part of the irregular plug-in should be corrected.

4. When soldering speakers and batteries, PCBA should pay attention to the amount of tin in the solder joints. If the amount of tin is too much, it may cause short circuit or even fall off of peripheral components.

During the inspection of plug-in welding quality, it was noticed that many weldments had only one taper on the solder surface, and there was no tin penetration in the through-hole. Functional testing confirmed that many of these parts were indeed welded. This issue was more prevalent in manual parts. The reason for this problem during the welding process was due to inappropriate temperature of the soldering iron and insufficient welding time. Poor permeability of polychlorinated biphenyl tin often led to false welding problems, resulting in additional rework costs. If the requirements for the permeability of polychlorinated biphenyl tin are high and the welding quality is strict, selective wave soldering can be used to reduce the problem of poor permeability of polychlorinated biphenyl tin effectively.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108