* On your first PCB Assembly order!

* Up to $300 discount

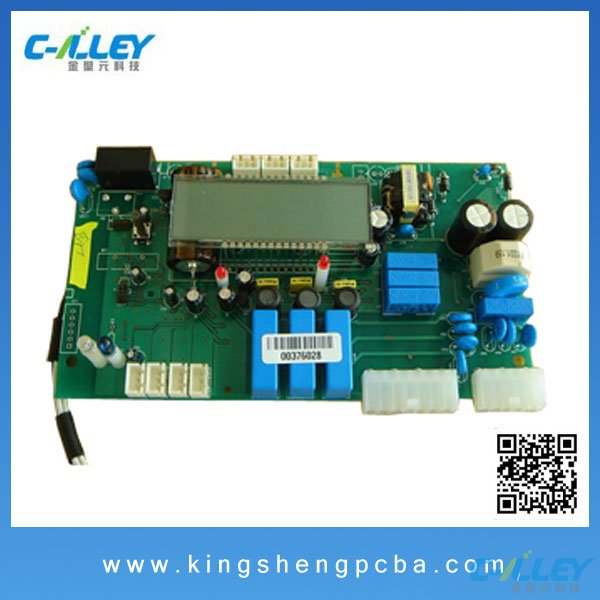

Product Name Electricity Meter PCBA

1.KingshengPCBA Turnkey solution for Electricity Meter PCBA

2.PCB Assembly, PCB/PCBA Design, PCBA Copy

3.Customized PCBA/OEM/ODM/EMS(Electronics Manufacturing Service)

4.SMT&DIP&PTH&BGA Assembly

5.Component sourcing and purchasing

6.Quick PCBA prototyping

7.Test:X-Ray,AOI,In-Circuit Test(ICT),Functional Test(FCT)

What Is Electricity Meter PCB?

An electricity meter PCB is a circuit board that measures energy usage in various applications. It is typically used to measure energy consumption in a home or industrial environment. Still, it can also be applied in energy-related research and development projects.

The electricity meter PCB is equipped with sensors that measure energy use, such as voltage and current. This data is then presented on a monitor or LCD. As a result, electricity meter printed circuits are efficient and reliable, delivering accurate energy readings in minutes. In addition, monitoring energy consumption over time allows users to determine energy usage trends and adjust correspondingly. With their advanced technology, electricity meter PCBs are an invaluable tool for energy management professionals. At KSPCBA, we manufacture high-quality energy meter PCBs.

Electricity Meter PCB Assembly

The components on the PCB of your power meter can be assembled using both surface mounting and through-hole mounting methods. However, you must mark the spot where each component will be attached before constructing the PCB with the components.

You can begin the soldering process after the electronic components are positioned where you want them to be put.

Reflow or manual soldering may be required for this. A worker who uses manual soldering must have experience soldering components by hand. Additionally, the PCB would go through an oven if reflow soldering was used. The PCB is soldered while the board goes through the oven. You must check the soldering quality after soldering. You must remove any faulty boards that may be present.

PCBA Manufacturing Service

PCB files, PCB technical requirements, BOM, Assembly or soldering technical requirements, to be offered by customer.

One Stop PCBA service: Production of PCB from 1-32 Layer, Assembly components/material purchase, SMT production, PCBA Testing, PCBA aging,PCBA Packaging, PCBA Delivery.

PCBA Manufacturing Quality

1. CE-EMC, UL, FCC, SGS, ROHS, ISO9001:2008, ISO14001:2004, TS16949 Certified.

2. 8 Dustproof SMT Lines and DIP Lines.

3. ESD and dust proof working uniform implemented.

4. Operators are strictly trained, and approved for suitable working station.

5. PCBA Production Equipments:HITACHI Screen Printer,FUJI NXT-II & FUJI XPF-L Modules

Automatic Solder-Paste Printer,Reflow Oven,Wave Solder Machine,AI DIP Machine.

6. PCBA Testing Equipments:ORT Machine,Drop Test Machine,Temperature & Humidity Test Chamber, 3D CMM, ROHS Inspection Machine,AOI, X-RAY Inspection.

7. PCBA Testing Capability:AOI(Automatic Optic Inspection),ICT(In-Circuit Test),FCT(Functional Circuit Test),X-Ray for BGAs.

8. Component Package including

Component range:

* 01005,0201,0402,0603,0805,1206,1608,2125,3216

* Fine Pitch QFP to 0.2mm

* BGA, Flip Chips, Connectors

* BGA to 0.2mm

9. SOP in every Work Station

10. PCB Materials: FR4, CEM-3, FPC, ALU

PCBA Manufacturing Delivery Duration

Delivery for samples will be 10-15 WD after OEM Contact is signed and the Engineering Documents are confirmed.

For Mass production, based on the customer requirements, delivery can be done in several steps (Partial Delivery).

PCBA Manufacturing Additional Information

1. After the confirmation of Prototype, MP will be started.

2. DIP Components will be positioned only once, minimum distance between components and PCB Board will be maintained.

3. Positioning Holes and Grounding holes will be protected by high temperature resistance tape.

4. EPE Antistatic packaging is used to prevent shock and other problems.

PCBA Shipment

Standard Package

Each PCBA unit will be in Anti static bag, then the bubble bags, and then put into PCBA special carton

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108