* On your first PCB Assembly order!

* Up to $300 discount

Kingsheng has extensive experience in software programming and function testing, with a team of experienced programmers and testers who are proficient in various programming languages and software development tools. They use advanced equipment and techniques to conduct function testing and ensure that the final product meets customer expectations and industry standards.

Kingsheng's IC programming and function testing service is a process of programming and testing integrated circuits (ICs) for electronic devices and systems.

IC programming involves writing data or instructions onto an IC, which will enable the device to perform a specific function or operation. Function testing involves verifying that the IC operates as intended and meets all performance requirements.

They use advanced equipment and software tools to program various types of ICs, including microcontrollers, memory chips, and programmable logic devices.

Kingsheng conducts thorough function testing to ensure that the ICs operate as intended and meet all performance requirements.

Kingsheng conducts thorough function testing to ensure that the ICs operate as intended and meet all performance requirements.

Kingsheng conducts thorough quality control checks to ensure that all ICs are programmed correctly and meet industry standards.

Kingsheng conducts thorough function testing to ensure that the software operates as intended and meets all performance requirements.

PCB Assembly technology plays a key role in today’s various intelligent devices. Integrated circuits (ICs) are an essential component of many electronic devices and systems, such as computers, smartphones, automotive electronics, and medical devices. IC programming is necessary to ensure that the IC performs the function or operation for which it was designed.

Kingsheng IC Programming Service provides a comprehensive and reliable solution for integrated circuit (IC) programming needs. Here are some of the features of Kingsheng's IC programming services:

Kingsheng can program various types of ICs including microcontrollers, memory chips, and programmable logic devices.

Kingsheng uses advanced programming equipment and software to ensure accurate and error-free programming of ICs.

Before programming, Kingsheng can test and verify the ICs to ensure they are functioning properly and there are no defects that could affect the programming process.

Kingsheng can package programmed ICs in tape and reel format for ease of use in manufacturing.

Kingsheng can serialize programmed ICs with unique identification numbers for traceability purposes and to prevent counterfeiting.

Kingsheng can develop customized programming algorithms based on customer requirements and provide customized labeling and packaging services for

IC programming is also called IC burning. Programming, the process of transferring a program into a chip can vary depending on the type of chip and programming hardware/software being used. It is always recommended to refer to the manufacturer's instructions and guidelines before attempting to program a chip. There are offline programming and online programming.

IC chip programming methods vary depending on the manufacturer and the specific device used. Some methods, such as in-circuit programming, can program the IC chip without removing it from the target system. Other methods involve placing the chip in a separate programming socket to configure it.

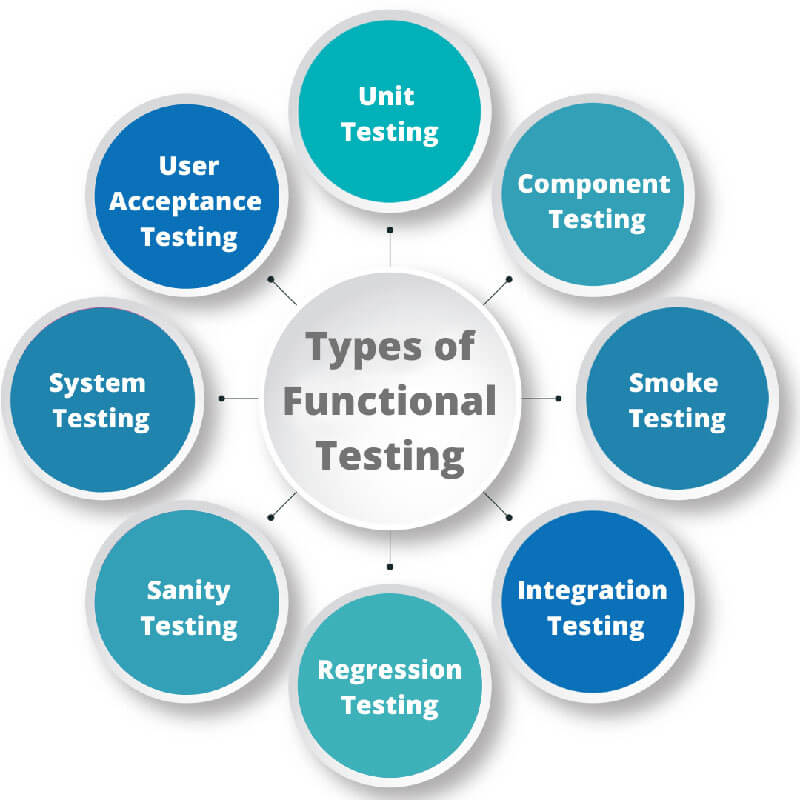

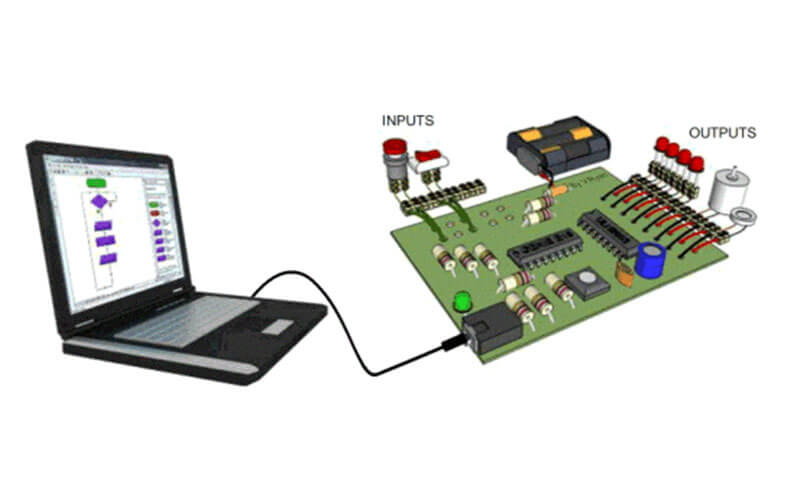

The FCT (Functional Circuit Testing) system is a testing method used to detect faults in electronic circuits. This system tests the functionality of a circuit by applying input stimuli to the circuit and measuring its output response. The FCT system is commonly used in the manufacturing industry as a quality control method for printed circuit boards (PCBs) and other electronic components. The FCT system typically includes a test fixture, which holds the PCB or component being tested, and a test program that instructs the system on how to apply the input stimuli and measure the output response. The test program can be automated, allowing for high-volume testing with minimal human intervention. The FCT system can detect a wide range of faults, including open circuits, short circuits, and incorrect component values. It can also verify that the circuit meets its design specifications and functional requirements.