* On your first PCB Assembly order!

* Up to $300 discount

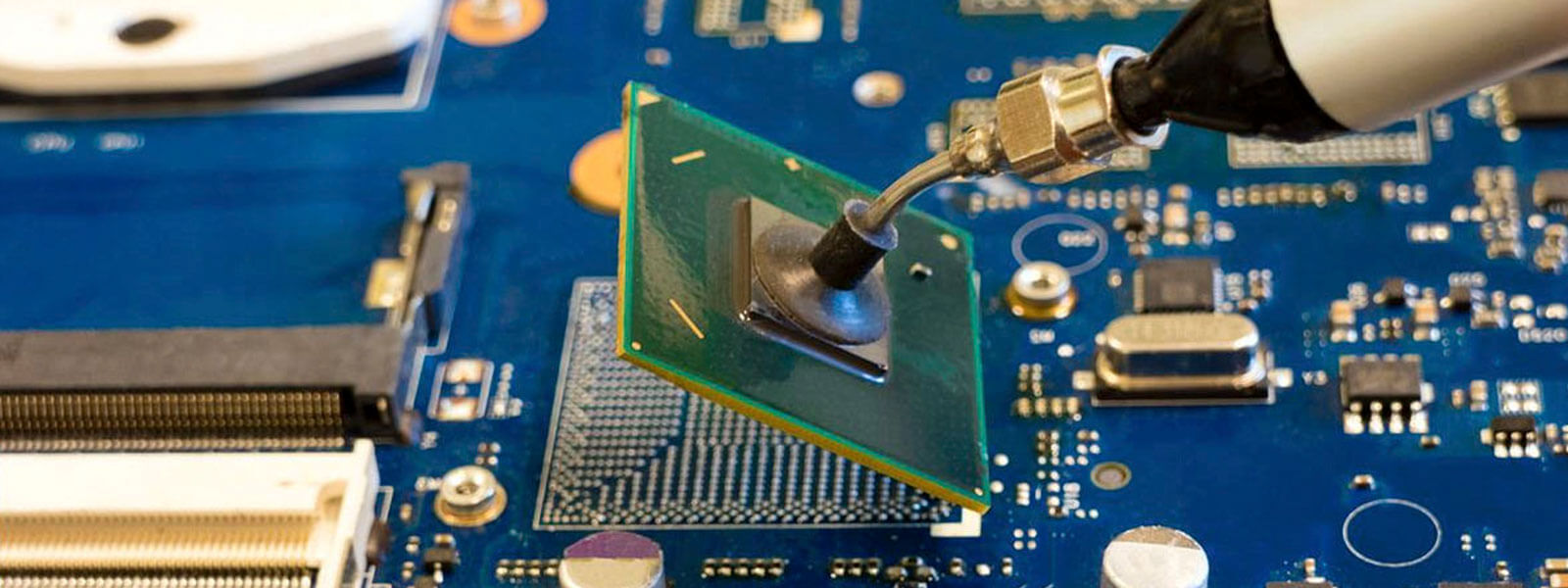

Kingsheng BGA (Ball Grid Array) Assembly is a process used for assembling electronic components onto PCBs using ball grid array technology. BGA technology involves attaching the component to the board using arrays of small solder balls instead of through-hole pins.This allows for a high density of connections in a small area, making it suitable for applications such as microprocessors, memory modules, and graphics chips.

Kingsheng's BGA assembly service uses advanced equipment and techniques to ensure high precision and reliability. They use automated optical inspection (AOI), X-ray inspection, and other testing methods to detect any defects or faults in the assembly process.

The first step is to design the PCB layout properly so that it accommodates the BGA component and its thermal requirements. The layout should be verified using a DFM (Design For Manufacturability) analysis.

The first step is to design the PCB layout properly so that it accommodates the BGA component and its thermal requirements. The layout should be verified using a DFM (Design For Manufacturability) analysis.

The first step is to design the PCB layout properly so that it accommodates the BGA component and its thermal requirements. The layout should be verified using a DFM (Design For Manufacturability) analysis.

The pick and place machines must be calibrated to ensure the BGA components are placed accurately on the PCB pads.

The reflow oven profile must be optimized to suit the BGA component and the PCB layout. The temperature profile should be strictly adhered to and recorded.

After the assembly process, an X-ray inspection should be performed to verify the BGA’s placement and soldering.

Once the BGA assembly is done, functional testing should be carried out to verify the circuit's performance. and robust circuit board.

The first step in the BGA assembly process is to prepare the PCB by applying solder paste to the appropriate locations where the BGA component will be mounted. This is done using a stencil that ensures precise application of the solder paste.

Once the PCB has been prepared, the BGA component is carefully placed on the PCB, aligning the solder balls with the corresponding solder pads on the PCB.

After BGA placement, the next step is to reflow solder the BGA component in place. Reflow soldering is a process where the PCB is heated in a specialized oven or reflow machine, causing the solder to melt and bond with the component and PCB pads.

Once the BGA component has been soldered in place, it undergoes a thorough inspection to verify that all solder balls are properly aligned and bonded. This includes visual inspections and X-ray imaging to confirm that the connections are sound and functional.

After inspection, the assembled PCBs are cleaned to remove any flux residues or other contaminants that may remain from the soldering process. This improves the long-term reliability of the assembly.

Finally, the assembled PCBs are packaged and shipped to the customer or production line.

The Kingsheng BGA assembly process is commonly used for electronic components with high pin counts or smaller form factors than those supported by THT or SMT Assembly. While BGA assembly requires specialized instruments and expertise in electronic assembly, it provides enhanced mechanical strength, improved electrical performance, and reduced space requirements.

Kingsheng BGA Assembly requires careful planning and execution, as well as attention to detail and quality control measures throughout the process.We offer a reliable and cost-effective solution for you with required high-density and high-reliability BGA assemblies.