* On your first PCB Assembly order!

* Up to $300 discount

Kingsheng's BGA rework service is a process of removing, replacing, or repairing Ball Grid Array (BGA) components that have become damaged, faulty, or need to be upgraded.

BGA rework can be a challenging process, as these components are typically densely packed and require precise handling and soldering techniques. Kingsheng has the expertise and equipment necessary to perform BGA rework with high precision and reliability.

Kingsheng BGA Rework methods refer to the techniques and equipment used for removing, replacing, and reflowing Ball Grid Array (BGA) components on a Printed Circuit Board (PCB). Here are some of the common Kingsheng BGA Rework methods:

This is one of the most common methods used for BGA rework. It involves applying hot air to the bottom of the PCB to melt the solder joints holding the BGA component in place, allowing it to be removed.

This method uses infrared heating systems to heat the PCB evenly, allowing the BGA component to be removed without damaging the surrounding components.

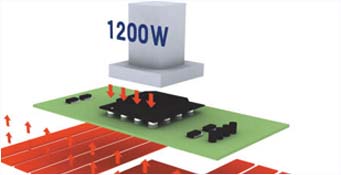

A specialized machine, such as a BGA rework station, can be used to heat the BGA component and melt the solder joints while simultaneously using a vacuum nozzle to lift off the chip from the PCB.

This method involves applying new solder paste to the pads on the PCB where the BGA component will be placed. The BGA component is then carefully placed on the pads, and the entire PCB is heated in an oven to melt the solder and reflow it around the new BGA component.

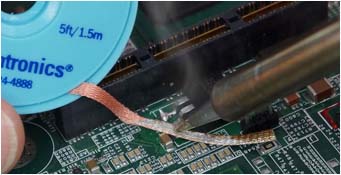

This method involves using a de-soldering braid to absorb the molten solder from the BGA component's solder joints during removal.

Kingsheng BGA Rework methods refer to the techniques and equipment used for removing, replacing, and reflowing Ball Grid Array (BGA) components on a Printed Circuit Board (PCB). Here are some of the common Kingsheng BGA Rework methods:

Kingsheng BGA Rework requires skilled technicians with extensive knowledge and experience in BGA rework. Ensure that the technicians performing the rework have adequate training and certifications.

The use of high-quality equipment, such as BGA rework stations, infrared heating systems, and desoldering braid, can help ensure consistency and accuracy during the BGA rework process.

Inspection is a critical step to ensure that the BGA component has been removed, replaced, and reflowed correctly. Inspect each step of the process to detect any defects or issues.

Proper documentation should be maintained to track the BGA rework process, including the specific methods used, rework parameters, active components, and post-rework testing results.

After the Kingsheng BGA Rework process is completed, post-rework testing should be carried out to ensure that the electronic device functions correctly under normal conditions.

Kingsheng BGA Rework should follow established guidelines and best practices to ensure that quality standards are met. These guidelines may include industry standards or manufacturer guidelines.

The Kingsheng BGA Rework process involves several steps to remove, replace, and reflow Ball Grid Array (BGA) components on a Printed Circuit Board (PCB). Here are the general steps involved:

The PCB is preheated using an infrared heating system or other appropriate techniques to prepare it for the BGA component removal.

The BGA component is removed by applying heat to the solder joints until they become molten. A specialized machine, such as a BGA rework station, may be used to remove the chip.

The area where the BGA component was removed is cleaned thoroughly to remove any residual solder or debris.

The PCB is inspected to ensure there are no damaged pads or traces that could interfere with the new component's installation.

The new BGA component is placed on the PCB, and the solder balls are aligned correctly with the pads.

The PCB is heated to melt the solder and reflow it around the new BGA component, creating a secure connection. Again, a specialized machine, such as a BGA rework station, may be used for this step.

In some cases, BGA components may be repaired rather than replaced, depending on the nature of the damage or fault. Kingsheng can perform component-level repairs to restore the functionality of the component.

Kingsheng conducts thorough quality control checks throughout the BGA rework process to ensure that all components are functioning properly and meet industry standards.

After reflow, the PCB is inspected again to ensure that the new BGA component has been installed correctly and that there are no defects or issues.

Kingsheng BGA Rework process requires skilled technicians, specialized equipment, and appropriate safety measures to ensure that the removal, replacement, and reflow of BGA components are carried out effectively and efficiently.