* On your first PCB Assembly order!

* Up to $300 discount

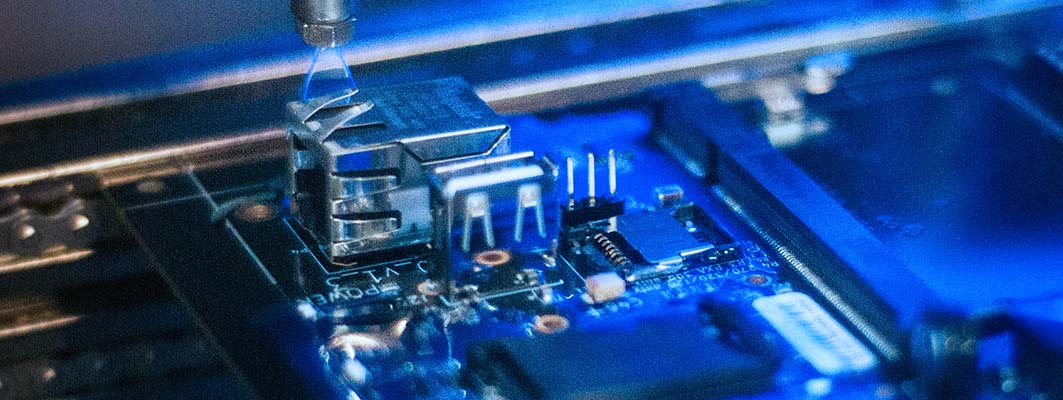

Kingsheng's Conformal coating service is a process of applying a protective coating to the surface of printed circuit boards (PCBs) and electronic components to protect them from environmental factors such as moisture, dust, chemicals, and temperature changes.

Conformal coating is a thin protective film that conforms to the contours of the PCB or component, providing a barrier against external elements that can cause damage or failure. The coating is typically applied using a spray, dip, or brush method and can be made from various materials, including acrylic, epoxy, silicone, and urethane.

Panelized assembly allows for multiple smaller boards to be assembled at once, reducing the number of assembly steps and increasing production efficiency

The coating can also improve the reliability and lifespan of electronic components by preventing corrosion and other forms of damage.

Panelized assemblies are easier to handle during the assembly process, reducing the risk of damage to the individual boards.

Conformal coating can help improve the safety of electronic devices by preventing electrical short circuits, promoting insulation, and reducing the risk of fire.

Kingsheng offers customized solutions tailored to meet the specific needs of each customer, including different types of coating materials and application methods.

Before applying conformal coating, the electronic components are cleaned thoroughly to remove any contaminants like dirt, oils, flux residues, or other particles that could affect the coating's adhesion.

The areas of the component that should not be coated with conformal coating are masked off using a masking material.

The conformal coating material is then applied to the electronic assembly using various methods such as spraying, dipping, or brushing, depending on the complexity of the electronic device and the type of coating used.

After the coating is applied, it needs to be cured to complete the chemical reaction and harden the coating. This is typically done in an oven set at a specific temperature and time.

Once the curing process is completed, each component is inspected to ensure that the conformal coating has been applied correctly.

If any inconsistencies are found during inspection, the product may need to undergo re-work to fix the issues.

Kingsheng conformal coating process is critical for protecting electronic devices from environmental damage, ensuring that they function correctly and have a longer lifespan.