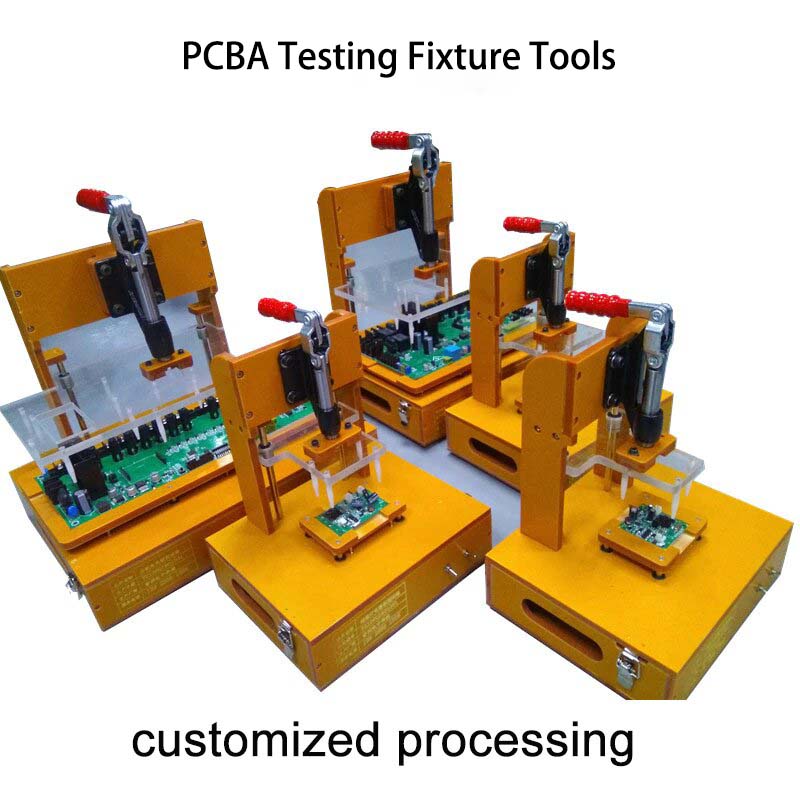

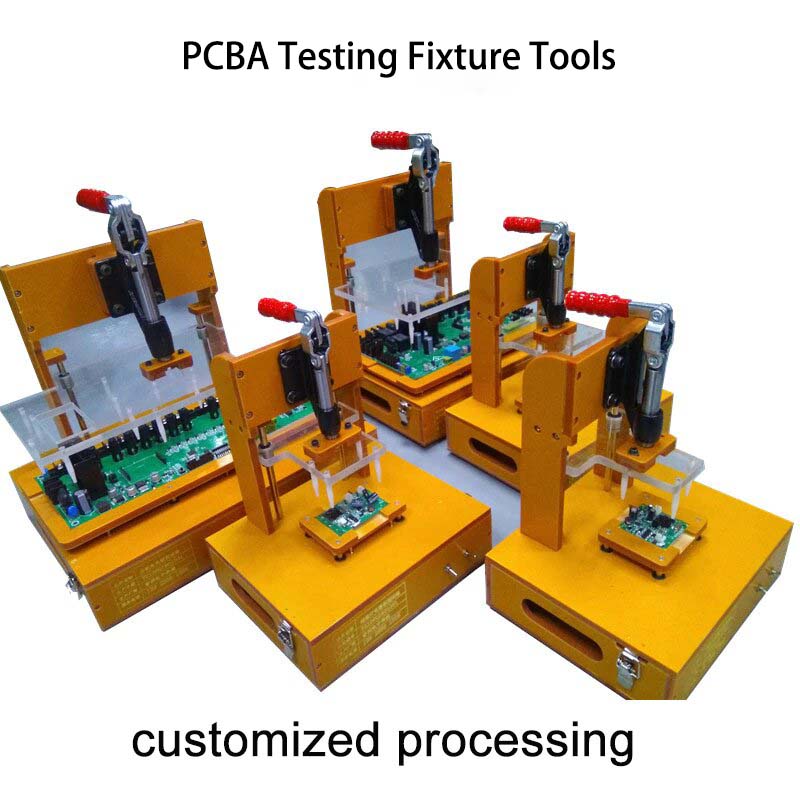

Generally speaking, a

PCBA testing fixture is a fixture specially customized for a certain product, which can effectively improve productivity and product quality.

Firstly, concerning PCBA testing fixture classification:

1. ICT test mainly includes circuit on-off, voltage and current values, fluctuation curve, amplitude, noise, etc.

2. FCT testing requires IC program firing, simulation testing of the function of the entire PCBA, in order to find problems in hardware and software, and make necessary production fixtures and testing jig.

3. The fatigue test is mainly for the PCBA sampled, and carries out the high-frequency, long-term operation of the function, observes whether there is a failure, judges the probability of test failure, and gets feedback on the working performance of the PCBA of electronic products.

4. The test in a harsh environment is mainly to expose the PCBA to the temperature, humidity, drop, splash, and vibration of the limit value, and obtain the test results of random samples, so as to infer the reliability of the entire batch PCBA.

5. The aging test is mainly to power the PCBA and electronic products for a long time, maintain their work, and observe whether there are any failures caused by invalidation, and the electronic products after the aging test can be sold for mass production order.

Secondly, regarding PCBA testing fixture process techniques:

1. According to the testing requirements and testing board, after selecting the control mode, the structure of the fixture can be designed, the support plate, pressure plate, and connector module can be designed, and the location of the support plate and pressure plate for the fixture is reasonably avoided, and there are corresponding protective measures to avoid damage to the test board when testing the product.

2. The positioning of the fixture is accurate, and the docking of connectors should be smooth.

3. The layout in the fixer box is reasonable, and there is sufficient space for wiring and control system installation.

4. The optical fiber/mic/SPK/SIM card analog card slot should be reserved and the position should be accurate.

5. The interface position reserved by the fixture should be correct, sufficient, and laid out reasonably.

6. The fixture box locking should be carried out by means of luggage buckle or press buckle to facilitate parts replacement and maintenance.

7. Making correct zero-point corrections. The zero drift of the test fixture will be changed with the change of test conditions or the difference of the test fixture, so the zero correction of the open circuit and short circuit is very necessary. Therefore, the FCT testing fixture has open circuit and short circuit correction settings.

8. When the fixture has a broken pin and an aging problem, it can be replaced for maintenance to use continuously. But if when the fixture is damaged and could not be repaired, or the PCBA is changed by the customer, so as to be unable to use again, then it needs to be remade.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108