* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

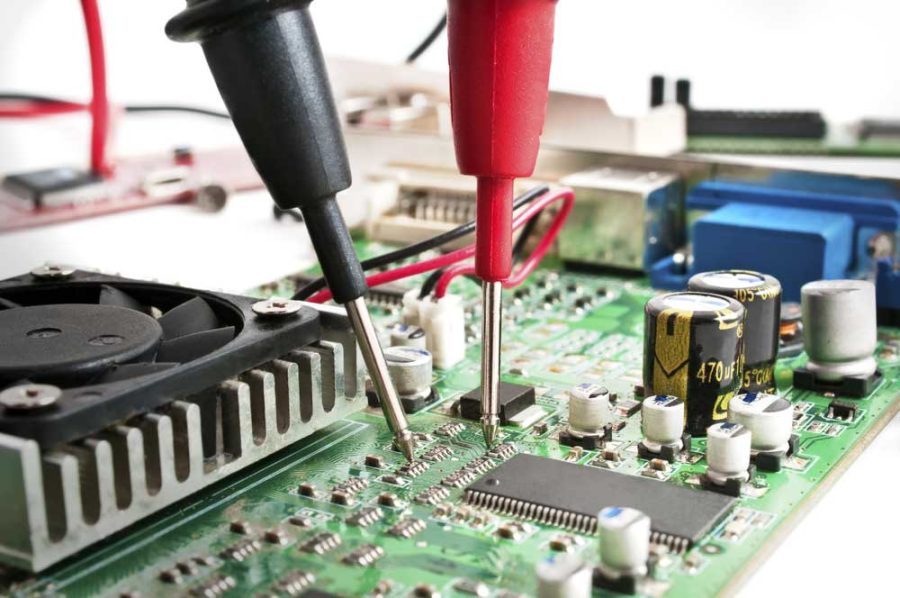

PCBA testing, also known as Printed Circuit Board Assembly testing, is an essential process where the assembled circuit boards are inspected to verify that they function correctly and meet design specifications. This testing involves identifying issues such as short circuits, soldering defects, and errors in component placement. Inspection methods can include visual checks, automated testing using specialized equipment, and functional tests that replicate real-world usage. Essentially, PCBA testing helps to identify and resolve potential problems before the boards are integrated into final products, ensuring the reliability and performance of electronic devices.

PCBA testing, which stands for Printed Circuit Board Assembly testing, encompasses comprehensive tests on PCBA boards for IC programming, line on-off conditions, current, voltage, and pressure. PCBA testing is a crucial quality control step in the entire PCBA production process, and strict testing standards must be followed to ensure the quality of shipments.

About PCBA Test Instructions

There are currently five main forms of PCBA testing:

1. ICT (In-Circuit Test) testing: This includes on-off, voltage, and current tests, as well as fluctuation curves, amplitude, and noise tests related to the circuit.

2. FCT (Functional Circuit Test) testing involves IC program firing and simulating the function of the entire PCBA board to identify hardware and software issues.

3. Aging testing: This test involves energizing the PCBA board and electronic products for a long time and observing for any failures. It ensures the longevity of the finished product.

4. Fatigue testing: This test entails subjecting the PCBA board to functional high-frequency and long-term operation to observe any failures, such as clicking the mouse 100,000 times or turning the LED light 10,000 times on and off.

5. Testing under harsh environments: This test exposes the PCBA board to extreme working environments, such as varying temperatures, humidity, drops, splashes, and vibrations, to assess the reliability of batch products.

After the final product undergoes these PCBA tests, the ones with no issues are labeled as qualified, packaged, and shipped.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Test Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108