* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

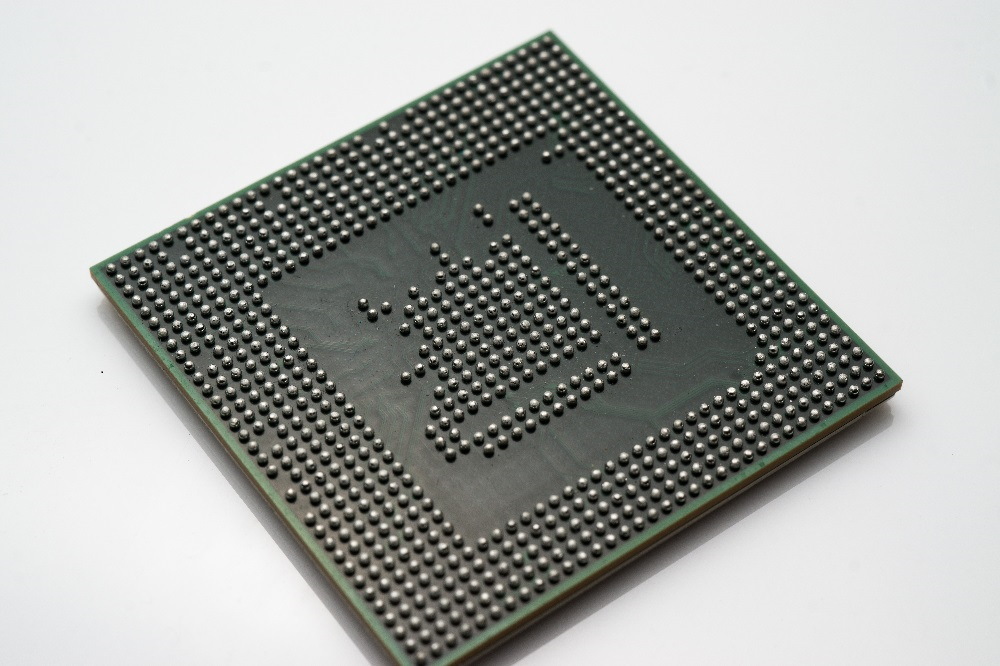

When considering the design requirements for producing sensitive computer components, it is clear that wire bonding can be challenging, particularly for surface-mounted devices. In the construction of microprocessors, where numerous terminals must be connected, Ball Grid Array (BGA) packages are preferred. BGAs are well-suited for developing computer components and other electronic devices.

BGAs are packages that permanently mount integrated circuits (ICs), memory chips, and microprocessor components onto the surface of a printed circuit board (PCB). Unlike traditional pin grid arrays (PGA) or dual in-line packages, BGAs connect to the PCB through small solder balls located on the bottom of the package.

As BGA devices become increasingly prevalent in electronic products, they have gradually established themselves as the mainstream technology in surface mount technology (SMT). However, producing high-quality BGA devices and maintaining a good assembly process can be technically challenging. It is essential to identify and manage the critical control points accurately.

Application of BGA Devices in Electronic Products

In the assembly of PCB electronic components, the goal is to achieve success on the first attempt. However, rework often becomes necessary because assembly defects cannot be entirely eliminated.

When rework is required, cost should be a primary consideration. If the rework cost exceeds the overall cost of the PCB, it may not be worth proceeding. Conversely, if cost is not a concern, necessary rework operations should aim to be minimized to avoid damaging the printed board and affecting quality, which can indirectly increase rework costs.

While rework may seem to only involve the component and the soldering method, other factors also contribute to the need for repairs. These include warping of printed boards, damaged pads, wiring errors, and misalignment during brazing.

Rework can be performed using hand tools, semi-automatic equipment, or fully automated systems. The purpose of rework tools is to remove and remount components by melting the solder at the junction of the component lead and the pad. Typically, hand tools and semi-automatic equipment are more practical than fully automated solutions. The effectiveness of rework also heavily depends on the skill of the operator, not just the quality of the equipment.

Reworking surface mount components with a soldering iron is usually not feasible due to limited accessibility to surface mount components, as well as small pads and leads. Additionally, the large number of solder joints in surface-mounted devices requires simultaneous rework, although the basic principles remain the same as for through-hole components.

When selecting rework tools or equipment, it is essential to consider their versatility and reliability. The type of board and components being reworked must also be taken into account. For instance, multi-layer boards, ceramic chip capacitors, and highly sensitive quad flat packages (QFPs) may require equipment with a warm-up function and a visual system. Furthermore, the size of the printed board and the distance between traces and components must be considered. If a tool or piece of equipment cannot meet the specifications of the board, it will be ineffective for the assembler.

Why Choose China PCBA Supplier KSPCBA as Your Application of BGA Devices in Electronic Products Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108