* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

In PCBA (Printed Circuit Board Assembly) processing, automotive-grade chips offer significant advantages over ordinary chips. One major reason for the higher cost of automotive electronic products is that they utilize vehicle-grade components during processing and production. Let's explore the key differences between the electronic components used in automobiles and those found in general consumer electronics.

1. Environmental Requirements

Temperature: Automotive electronics are designed to operate within a wide temperature range. Different installation locations dictate varying temperature requirements, but these specifications are generally more stringent than those for consumer products.

2. Vibration Resistance

Automobiles function in dynamic environments, exposing electronic products to substantial vibrations and impacts. Consequently, the requirements for automotive components in terms of vibration resistance are much higher than for those in other applications.

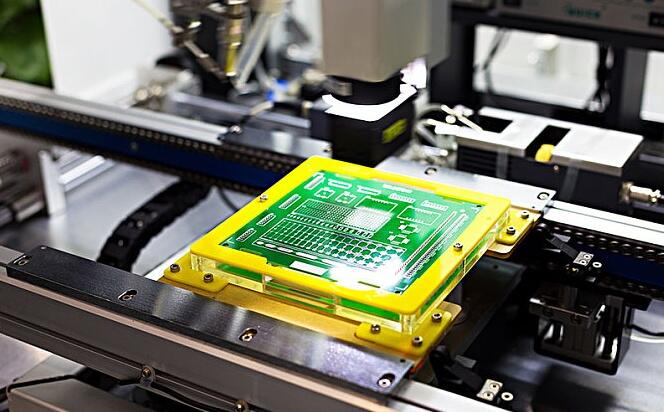

Car Gauge Chip In PCBA Processing

3. Reliability

To understand the reliability requirements for automotive electronics, consider the following points:

Design Life: The average design life of a standard automobile is typically around 150000 years and 200000 kilometers, which far exceeds the life expectations of consumer electronics.

Component Reliability: When maintaining the same reliability standards, systems with more components and connections require even higher reliability for each individual part. Modern vehicles are increasingly electronic, encompassing everything from powertrains to brake systems, each containing numerous electronic devices. To achieve overall vehicle reliability, each component must meet high performance standards, often expressed in parts per million (PPM).

4. Consistency Requirements

As automotive production has scaled, the demand for product quality consistency has intensified. A single model can result in hundreds of thousands of units produced annually, making uniformity crucial.

In the early days, achieving consistency in semiconductor production was challenging due to difficulties in controlling processes like diffusion. The resultant product performance often varied significantly, necessitating methods like aging and screening. However, ongoing advancements in manufacturing processes have significantly improved quality consistency. Ensuring high levels of consistency is essential, as components with subpar reliability may pose potential safety hazards in complex automotive systems.

In summary, automotive-grade chips are engineered to withstand more rigorous conditions and ensure higher reliability and consistency compared to ordinary chips, thereby justifying their higher cost.

Why Choose China PCBA Supplier KSPCBA as Your Car Gauge Chip In PCBA Processing Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108