* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

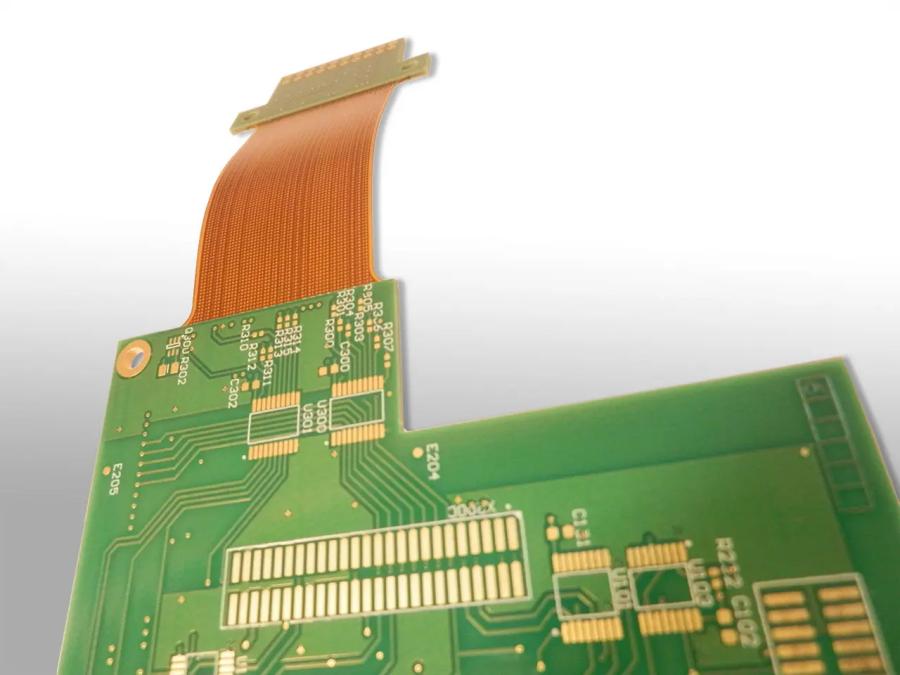

Flexible PCB Circuits: An Overview

Flexible PCB circuits are compact and lightweight circuit boards initially designed to replace larger harness wires. In today's advanced electronic device assemblies, flexible PCBs are often the only feasible solution to meet miniaturization and mobility requirements. These circuits, also known as flexible printed circuits, consist of copper circuits etched onto a polymer substrate or printed using polymer thick film technology.

For devices that require both thin and lightweight designs, solutions can range from simple single-sided conductive circuits to complex multi-layer, three-dimensional assemblies. Overall, the weight and volume of flexible assemblies can be reduced by up to 70% compared to traditional circular wire harness methods. Additionally, flexible PCBs can enhance mechanical strength by incorporating reinforcing materials or liners, providing greater stability.

Mobile Bending and Torsion

Flexible PCBs can move, bend, and twist without damaging the connections, adapting to various shapes and unique package sizes. Their primary limitation is related to volume space. Capable of withstanding millions of dynamic bends, flexible PCBs are ideally suited for applications involving continuous or periodic movement within connected systems, thus becoming integral to the final product's functionality. Unlike rigid PCBs, whose solder joints are prone to thermal mechanical stress and failure after just a few hundred cycles, flexible PCBs maintain their integrity under dynamic conditions.

Electrical Properties and Reliability

Flexible PCBs exhibit excellent electrical properties, including strong dielectric characteristics and heat resistance. They also improve assembly reliability and yield by minimizing the necessary hardware for internal connections, such as solder joints, trunks, baseplate lines, and cables commonly used in traditional electronic packages. Traditional embedded hardware involving complex multiple systems often suffers from a high dislocation rate during assembly. The advent of quality engineering has led to the design of thin flexible systems that can be assembled in only one orientation, significantly reducing the potential for human error associated with independent wiring engineering.

Characteristics and Efficacy of Flexible PCB Circuits

Types of Flexible PCBs

There are four primary types of flexible PCBs: single-sided, double-sided, multi-layer, and rigid-torsion combined.

1. Single-Sided Flexible PCBs When electrical performance requirements are not stringent and single-sided wiring is sufficient, single-sided flexible plates are used. This is the most common type and finds applications in products like printer ink cartridges and computer memory. A single-sided flexible plate features a layer of chemically etched conductive patterns on the surface of a flexible insulating substrate made from materials such as polyimide (Kapton), polyethylene terephthalate (PET), aramid fiber paper (Nomex), or polyvinyl chloride (PVC).

2. Double-Sided Flexible PCBs: These consist of conductive patterns etched on both sides of the base film. Metallized holes connect the patterns on both sides of the insulating material, forming a conductive pathway necessary for flexible designs and functionality. A covering film is often used to protect the wires and indicate component positioning.

3. Multi-Layer Flexible PCBs: These involve stacking three or more layers of single-sided or double-sided flexible PCBs. Through drilling and electroplating to create metallized holes, a conductive pathway is established between different layers, eliminating the need for complex soldering processes.

By understanding these aspects of flexible PCBs, designers can make informed choices for their electronic device assembly needs.**Flexible PCB Circuits: An Overview**

Flexible PCB circuits are compact and lightweight circuit boards initially designed to replace larger harness wires. In today's advanced electronic device assemblies, flexible PCBs are often the only feasible solution to meet miniaturization and mobility requirements. These circuits, also known as flexible printed circuits, consist of copper circuits etched onto a polymer substrate or printed using polymer thick film technology.

For devices that require both thin and lightweight designs, solutions can range from simple single-sided conductive circuits to complex multi-layer, three-dimensional assemblies. Overall, the weight and volume of flexible assemblies can be reduced by up to 70% compared to traditional circular wire harness methods. Additionally, flexible PCBs can enhance mechanical strength by incorporating reinforcing materials or liners, providing greater stability. Flexible PCBs can move, bend, and twist without damaging the connections, adapting to various shapes and unique package sizes. Their primary limitation is related to volume space. Capable of withstanding millions of dynamic bends, flexibl.

Why Choose China PCBA Supplier KSPCBA as Your Flexible PCB Circuits Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108