* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

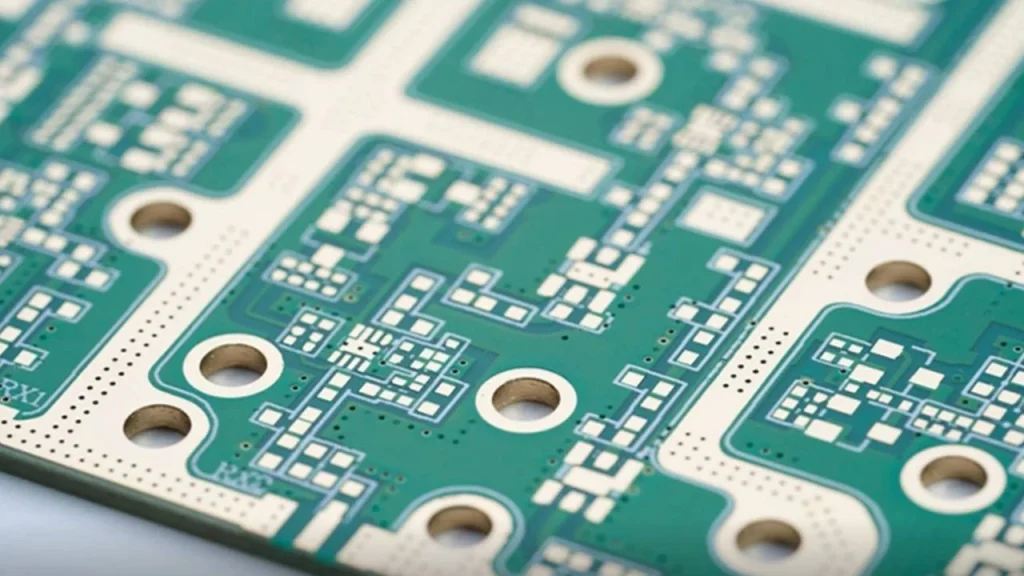

When manufacturing high-quality PCBS, different PCB surface treatment processes have different effects on the performance and reliability of the PCB.

KingshengPCBA will introduce several common surface treatment processes, including anti-oxidation, spray tin, lead-free spray tin, sunk gold, sunk tin, sunk silver, hard gold plating, full plate gold plating, gold finger, nickel palladium and OSP, and discuss their characteristics and options for different applications.

Antioxidant treatment

Antioxidant treatment is a process that protects the PCB surface from oxidation. It is usually gold-plated or tinned, and the metal layer is covered on the surface of the PCB to prevent oxygen and moisture from eroding the PCB.

This process has low cost and good weldability, but requires harsh storage conditions, short time, and is not suitable for long-term storage. Anti-oxidation treatment is an environmentally friendly process with good welding effect and smooth surface.

Tin spray treatment

Tin spray treatment is usually used for multi-layer high-precision PCB templates, especially boards with 4 to 46 layers. This process involves spraying tin on the PCB surface to form a uniform tin layer. Tin spray plate is widely used in communication, computer, medical equipment and aerospace and other fields.

One such application is the Goldfinger, which is a connector on a memory strip to a memory slot for transmitting signals. Gold fingers consist of conductive contact pieces, usually gold-plated to ensure good electrical conductivity. However, due to the high price of gold, some equipment has begun to use tin plating instead of gold plating, especially price sensitive equipment.

Common PCB Surface Treatment

Gold Plating

Gold plating is a common surface treatment process, especially suitable for high-density PCBS. It solves some problems of tinspray treatment, such as pad flatness and short service life.

metallization

Sinking of gold is a high quality surface treatment process with some advantages. First of all, the crystal structure formed by sinking gold and gold plating is different, golden, and customers are more satisfied. Secondly, sinking gold is easier to weld than gold plating, will not cause welding problems, and is not easy to produce poor welding.

The submerged metal plate has obvious advantages in the high density PCB and ultra-small surface paste process. Its golden color is more popular, the welding effect is better, and it is not easy to produce welding problems. In addition, the crystal structure of the sunk gold plate is different, and the skin effect is less affected, which is suitable for high-frequency signal transmission.

1. Is antioxidant treatment environmentally friendly?

Yes, antioxidant treatment is an environmentally friendly process that can protect the PCB surface from oxidation and extend the service life of the PCB.

2. What is the service life of the sunken gold plate?

The service life of the sunk gold plate is usually longer than that of the gold-plated plate, and can be stored for several months or even longer.

3. Which applications are tin spray plates suitable for?

Tin-spray plates are usually used for multi-layer high-precision PCB templates, especially boards with 4 to 46 layers. It is widely used in communications, computers, medical devices and aerospace, including connecting parts such as goldfingers.

Why Choose China PCBA Supplier KSPCBA as Your PCB Surface Treatment Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108