* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

The two main types of PCBs are flexible PCB circuit boards and rigid PCB boards. Rigid PCBs are inflexible, while flexible PCBs can be easily bent or shaped to fit the specified system. Although rigid and flexible PCBs are still popular due to their low cost, flexible PCBs have recently gained market share based on their versatility and other advantages. Flexible boards are recommended and preferred for the following reasons:

1. Flexibility of Flexible PCBs

Flexible PCBs are popular because they can be easily bent, folded, or creased to fit or match the end application. This flexibility allows designers to fit the circuits to the equipment, rather than building the equipment around the circuit boards. Flexible PCBs are suitable for wearable electronic devices, medical devices, foldable mobile phones, sensors, and implants.

2. Connectivity of Flexible PCBs

Flexible PCBs provide excellent connectivity between other circuit boards, user interfaces, and electronic components. They are preferred in applications where the circuit needs to be constantly bent over the working life of the device. Flexible PCBs have been widely used in foldable electronic products, laptop computers, and display connections.

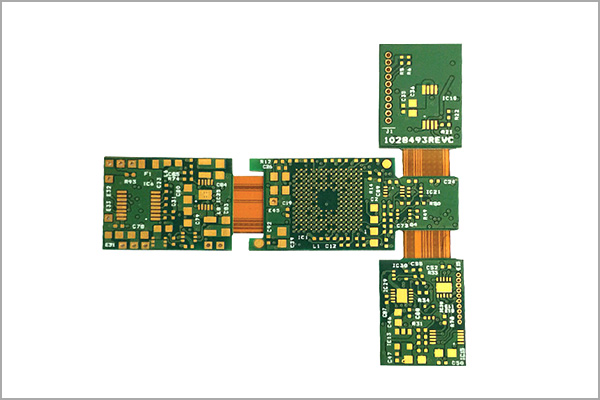

Comparison between rigid PCB and flexible PCB

3. Role of Flexible Circuits

Flexible printed circuit boards will not completely replace rigid printed circuit boards for all applications due to cost efficiency. Innovative products incorporate flexible circuits when necessary, while using stable and reliable rigid circuit boards to reduce assembly and manufacturing costs. Some manufacturers use hybrid rigid-flex PCBs to reduce costs. Rigid-flex PCBs are widely used in medical equipment and notebook computers, where rigid boards are connected using ribbon-shaped flexible circuits.

4. Durability of Flexible PCBs

Flexible PCBs can withstand shock and vibration more effectively than rigid PCBs, contributing to long-term reliability, functionality, and product life. Flexible PCBs are widely used in weapons, missile guidance systems, medical electronics, satellites, and applications that require excellent environmental survivability.

Cost of Flexible PCBs

Flexible printed circuit boards are slightly more expensive to manufacture and install than rigid printed circuit boards. They require the creation of additional engineering files and may include coverlays, pressure-sensitive adhesives, and stiffeners. Although the manufacturing and installation costs of rigid printed circuit boards are lower, the advantages of flexible printed circuit boards, such as durability and functionality, make them a preferred choice for many engineers. However, it is worth noting that the cost usually increases as the number of layers increases.

Why Choose China PCBA Supplier KSPCBA as Your rigid PCB and flexible PCB Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108