* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

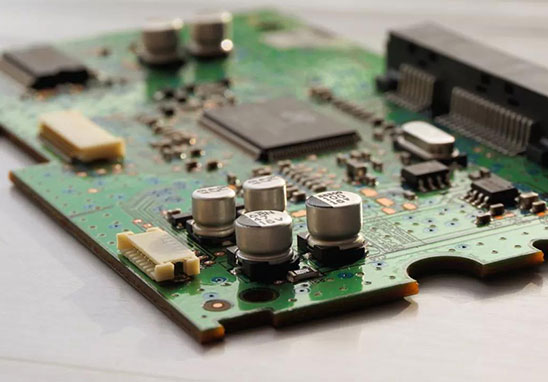

Summary of Key Points on the Assembly Process for PCBA Processing of Electronic Products

1. The assembly of electronic products involves combining and connecting various electronic components, assemblies, electromechanical components, and structural parts at designated positions according to design specifications. This process creates a complete electronic product with specific functions.

2. The overall assembly of electronic products is categorized into component level, plug-in level, and system level assemblies. Assembly methods include functional assembly, component assembly, and functional component assembly.

3. The assembly process comprises both manual and automatic methods. Manual assembly can involve individual worker assembly or assembly along an assembly line, which may operate in two forms: free beat or forced beat. Automatic assembly requires standardized components and dimensions, with the shapes and sizes of components kept as simple and consistent as possible.

4. The complete assembly of electronic products includes two main steps: electrical assembly and structural installation. The overall assembly process typically consists of several stages: matching preparation of parts and components, assembly and connection of parts, commissioning of the entire machine, general assembly inspection, packaging, and warehousing or delivery.

Complete assembly of PCBA processing electronic products

5. In addition to welding, other connection methods such as crimping, winding, bonding, and threaded connections are also utilized during the assembly of electronic products. Most installations require the fastening of screws, while some parts only need simple plugging. Some connections are removable, while others are not.

6. The installation of the complete electronic product is defined as the final assembly, which occurs after a qualified installation inspection of all parts and components. Most processes follow a flow method, with typical assembly sequences being: lighter items assembled before heavier ones, smaller items before larger ones, riveting before installation, interior components before exterior ones, lower items before higher ones, and fragile parts before installation. The previous process should not hinder the installation of the next step.

7. Inspection of electronic products includes pre-warehouse inspection and production inspection. It is essential to adhere to the "three inspection" principle, which includes self-inspection, mutual inspection, and full-time inspection. Overall quality inspection encompasses appearance checks, correctness of assembly, safety checks, and type testing.

8. Full-time inspection of complete machine products comprises both full inspections and sampling inspections. This includes visual inspections, functional checks, and testing of main performance indices. Routine tests may include environmental assessments and life testing.

9. Packaging serves a dual purpose: protecting electronic products and enhancing the promotion of products and enterprises. The packaging requirements for electronic products involve protection specific to electronic components as well as general packaging standards.

10. The technical measures for electronic product packaging include shockproofing, moisture-proofing, dust-proofing, anti-static measures, and heat resistance. Packaging materials used may include corrugated boxes, wooden boxes, cardboard packaging, and various cushioning materials such as plastic foam, bubble film, and corrugated paper, along with moisture-proof, anti-static, and heat-resistant materials.

This summary outlines the key points regarding PCB design and the entire assembly process of PCBA processing for electronic products.

Why Choose China PCBA Supplier KSPCBA as Your PCBA processing electronic products Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108