* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

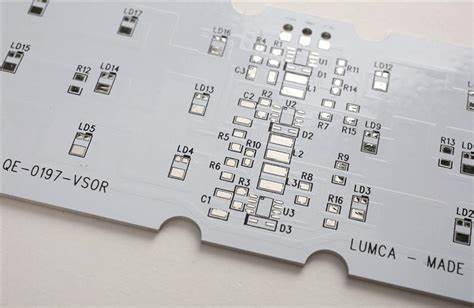

The PCB board we commonly use is coated with copper on one or both sides of the insulating board's surface. In the specific form of a PCB, the aluminum substrate is usually coated with copper on one side, and the insulating layer is very thin. Then, the aluminum board is superimposed on the side without copper coating, creating what's known as an aluminum substrate. These are typically used in audio, power supply, communication electronic equipment, automobiles, computers, lamps, and lighting.

Advantages of aluminum substrates:

1. Good heat dissipation performance: The aluminum substrate minimizes thermal resistance and has excellent thermal conductivity, reducing the operating temperature of the module and extending the service life.

Discussion On Aluminum Substrate

2. High current carrying capacity: With the same thickness and line width, the aluminum substrate can carry a higher current.

3. Good machinability: It can replace ceramic substrates and has better mechanical durability, high strength, and toughness, allowing for large-area PCB manufacturing and component mounting.

4. Good electromagnetic wave shielding: The aluminum substrate can act as a shielding plate to shield electromagnetic waves.

5. Environmental protection: Aluminum used as raw material is non-toxic and recyclable, meeting ROHS requirements.

6. Light weight: Aluminum offers lightweight and convenient under excellent strength and elasticity conditions.

However, aluminum substrates still have some shortcomings in the existing market, such as:

1. High cost: The price of aluminum substrates is more than 30% compared to similar goods.

2. High process difficulty: Double-sided boards are difficult to manufacture, and the process is complex. Voltage and electrical strength are also prone to problems in the manufacturing process.

3. Lack of standardization: Material specifications are not unified across CPCA industry standards, national standards, and international standards.

Why Choose China PCBA Supplier KSPCBA as Your EMS Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108