* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

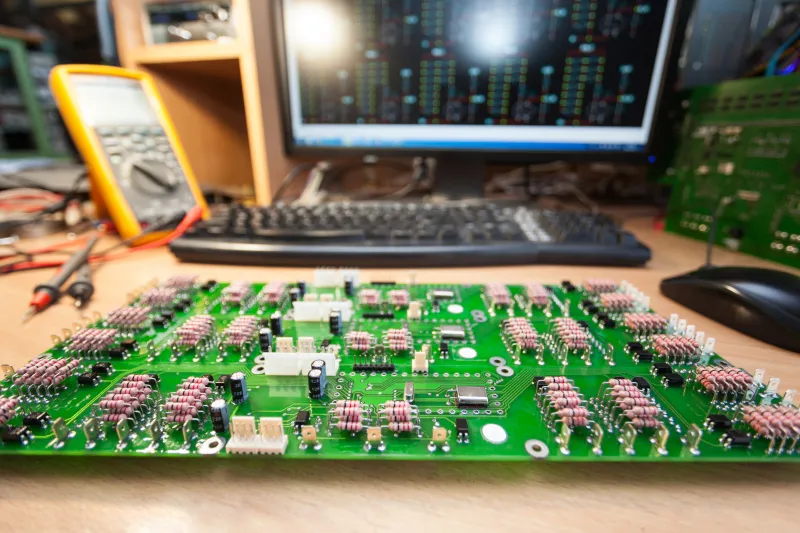

What are electrolytic capacitors?

An electrolytic capacitor is a type of capacitor that uses an electrolyte to achieve a larger capacitance than other capacitor types. An electrolyte is a liquid or gel containing a high concentration of ions. Almost all electrolytic capacitors are polarized, which means that the voltage on the positive terminal must always be greater than the voltage on the negative terminal.

However, the benefit of large capacitance in electrolytic capacitors comes with several drawbacks. Among these drawbacks are large leakage currents, value tolerances, equivalent series resistance, and a limited lifetime.

Electrolytic capacitors can be either wet-electrolyte or solid polymer and are commonly made of tantalum or aluminum, although other materials may also be used.

Supercapacitors are a special subtype of electrolytic capacitors, also called double-layer electrolytic capacitors, with capacitances of hundreds and thousands of farads.

Electrolytic Capacitor in The Role of PCB Design

1. Filter Effect

In the power supply circuit, the rectifier circuit converts alternating current into pulsating direct current. After the rectifier circuit, a larger-capacity electrolytic capacitor is connected. This capacitor changes the pulsating direct current voltage after rectification into a relatively stable direct current voltage with a charge-discharge characteristic.

To prevent the various parts of the PCB manufacturing circuit supply voltage changes due to load changes, the power output and the load power input generally receive electrolytic capacitors that range from tens to hundreds of microfarads. However, as large-capacity electrolytic capacitors generally have a certain inductance, they cannot effectively filter out high-frequency and pulse interference signals. Therefore, at both ends, in parallel with a capacity of 0.001--0.1 µF capacitor, it is recommended to filter out high-frequency and pulse interference signals.

2. The Coupling Effect

In the process of transmission and amplification of low-frequency signals, capacitive coupling is often used to prevent the static operating points of the two stages of circuits from interfering with each other. To prevent the signal rhyme low-frequency component loss is too large, larger capacity electrolytic capacitors are commonly used.

Electrolytic Capacitor in The Role of PCB Design

Method to Determine the Electrolytic Capacitor Fault

Electrolytic capacitors commonly develop faults such as capacity reduction, capacity loss, breakdown short circuits, and leakage. Capacity change occurs due to the use of electrolytic capacitors or through the process of placing them, and the internal electrolyte gradually dries up. Breakdown and leakage generally occur due to an added voltage that is too high or due to poor quality.

Method to Determine the Quality of PCB-Proofing Power Capacitors

The resistance of the multimeter is generally used to measure the quality of PCB-proofing power capacitors. The specific method is as follows:

1. Short-circuit the two capacitors and discharge them.

2. With a black meter pen, measure the positive electrolytic capacitor.

3. Measure the negative with the red pen (on the pointer multimeter, with a digital multimeter test pen intermodulation).

4. The normal needle should first swing in the direction of small resistance and then gradually return until the infinity department. The greater the swing amplitude of the hands or the slower the speed of return, the greater the capacity of the capacitor. Conversely, the smaller the capacity of the capacitor, the smaller the swing amplitude of the hands or the faster the speed of return.

5. If the index finger in the middle no longer changes, it indicates that the capacitance is leaking. If the resistance indication is small or zero, it indicates that this capacitor has been broken down short circuit.

It is essential to note that the voltage of the battery used by the multimeter is generally very low. Therefore, when measuring the capacitor with a lower withstand voltage, the measurement is more accurate. When the capacitor with higher withstand voltage is measured, although the measurement is normal at the time of the blowout, leakage or blowout may occur under a high voltage wear phenomenon.

Why Choose China PCBA Supplier KSPCBA as Your PCB Design Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108