* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

The Failure Mechanisms of Components on PCBA Boards: An In-depth Analysis

Electrolytic capacitors and certain types of film capacitors are susceptible to failure due to chemical reactions within their dielectrics, which can be initiated by trace impurities such as oxygen in conjunction with electrical stress.

Integrated circuits have been shrinking in size following Moore's Law, leading to an increased risk of device failure over decades rather than centuries due to dopant migration at normal operating temperatures. Additionally, magnetostriction-induced fatigue can cause mechanical wear in inductors, a well-documented phenomenon. Some resistive materials may gradually oxidize in air, with the rate of oxidation accelerating under humid conditions. Similarly, batteries do not last indefinitely.

When selecting components, it is essential to understand their structures and potential aging-related failure mechanisms. Even under ideal operating conditions, these mechanisms can still impact device performance. Although this article does not delve deeply into failure mechanisms, reputable manufacturers typically consider product aging and are familiar with the expected lifespan and potential failure modes of their devices. Many system manufacturers provide information on the safe operating life of their products and their limiting factors.

Under proper working conditions, most electronic devices can have a lifespan of several decades or longer; however, some may fail prematurely due to unnoticed stresses.

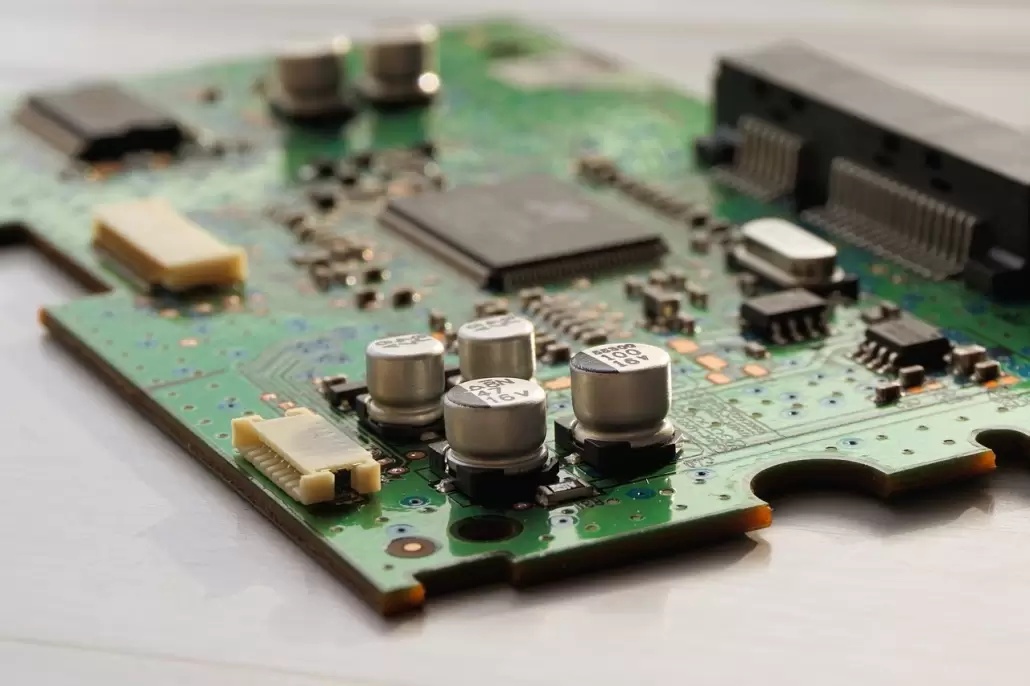

Explanation of Components on PCBA Board

Designers of electronic products for marine environments generally account for challenges like salt fog and humidity, which can be detrimental. However, many less obvious chemical challenges can also impact electronic devices. For example, human (and animal) respiration contains moisture and is slightly acidic. Home environments, such as kitchens, can produce various mildly corrosive substances, including bleach, disinfectants, cooking smoke, oil, and alcohol. While these substances may not seem harmful, assuming circuit safety under sound protection is a mistake. Designers must consider environmental challenges and aim to minimize potential hazards through design whenever economically viable.

Electrostatic damage (ESD) is a significant stress mechanism, often overlooked despite common ESD warnings. During PCB production, factories typically implement measures to prevent ESD. However, once delivered, many printed circuit boards are used in systems lacking adequate ESD protection from routine operations. Implementing robust ESD protection is relatively straightforward but is often neglected due to cost considerations, especially during economic downturns. All designs must evaluate necessary ESD protection systems for electronic components and consider effective implementation.

Another factor to consider is overvoltage. While few people expect semiconductors or capacitors to remain safe under significant overvoltage conditions, high-value resistors are frequently exposed to voltages exceeding absolute maximum ratings specified in data sheets. Although high resistance values may prevent overheating, small internal arcs can form, leading to gradual drift from specifications and eventual short circuits. Traditionally, large winding resistors could withstand breakdown voltages of several hundred volts. However, the widespread use of small surface-mounted resistors has changed this, with breakdown voltages as low as 30 volts, making them particularly susceptible to overvoltage conditions.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Board Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108