* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

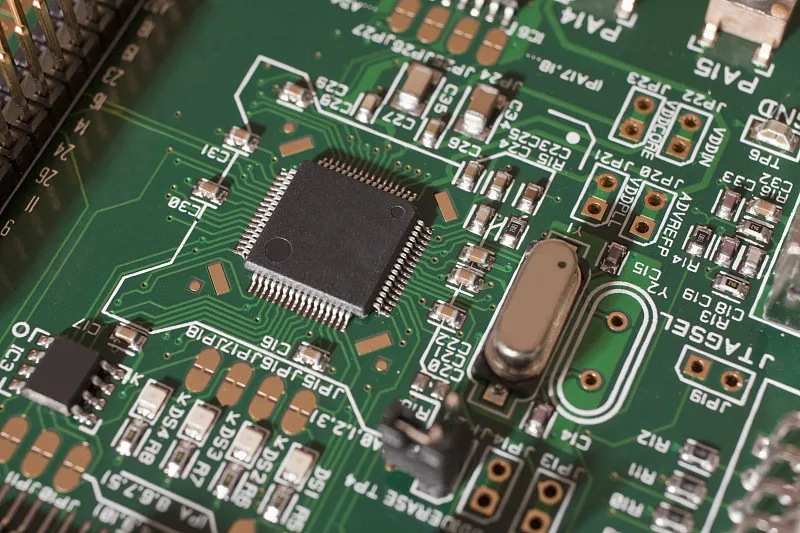

The support height (the space between the PCB and the ground clearance) is likewise getting smaller and smaller as the density and size of PCBA components increase. Additionally, the PCBA is affected by environmental factors. The impact is growing and increasing the demands placed on the PCBA reliability of electrical equipment. The following KSPCBA briefly introduces the factors that cause poor PCB surface quality during the production and PCBA processing process.

1. When processing thin PCB substrates (usually below 0.8mm), the rigidity of the substrate can be poor, making it unsuitable to brush with a brushing machine. This can result in difficulty removing the protective layer that prevents oxidation of the copper foil on the board surface. Although this layer is thin and easy to remove with a brush, it can be difficult to treat chemically.

2. During machining (such as drilling, lamination, milling, etc.) of the PCB surface, the surface treatment can be poor due to oil or other liquid contaminated with dust.

3. Poor sinking copper brushing can occur due to excessive pressure from the sinking copper front grinding plate, causing hole deformation, brushing the hole copper foil rounded corners, and even substrate leakage. This can result in sinking copper electroplating, spraying tin soldering, and blistering at the orifice. Therefore, it is important to strengthen the control of the brushing process and adjust the brushing process parameters to appropriate values through wear scar tests and water film tests.

PCBA

The sensor market has seen a rise in recent years due to industrial modernization and the growth of the electronic information industry. Temperature sensors, which convert non-electrical physical quantities into electric sub-products by utilizing the characteristic that NTC resistance value changes with temperature, account for more than 40% of the total demand for sensors.

Capacitive touch has many advantages, including the ability to make the control panel of capacitive touch products arbitrary, and the touch panel can be made of insulating materials.The use of capacitive touch can improve the interaction between people and products, enhance product vitality, and stimulate customers' desire to buy products, ultimately increasing product sales.

Why Choose China PCBA Supplier KSPCBA as Your PCBA processing Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108