* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

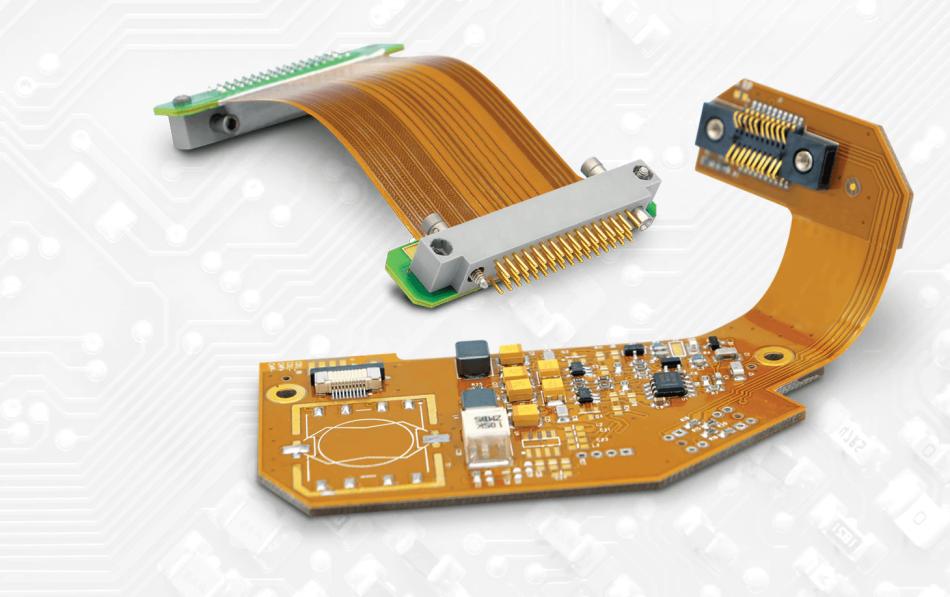

Flexible printed circuit boards (PCBs) have become increasingly popular in recent years due to their versatility, reliability, and ability to fit into compact spaces. These PCBs are made from flexible materials, such as polyimide or polyester, allowing them to bend, twist, and fold without losing their electrical integrity. Flexible PCBs are used in various industries, including consumer electronics, medical devices, automotive, aerospace, and more.

What are Flexible PCBs?

Flexible PCBs, also known as flex circuits or flexible printed circuits (FPCs), are a type of printed circuit board that uses flexible base materials instead of rigid substrates like FR-4. The conductive traces are printed on the flexible substrate, enabling the PCB to bend and conform to various shapes and sizes.

Advantages of Flexible PCBs

Flexible PCBs offer several advantages over traditional rigid PCBs:

Space-saving: Flexible PCBs can be folded, bent, or twisted to fit into tight spaces, making them ideal for compact electronic devices.

Weight reduction: The thin and lightweight nature of flexible PCBs helps reduce the overall weight of the end product.

Improved reliability: Flexible PCBs can withstand vibrations, shocks, and extreme temperatures better than rigid PCBs, enhancing their reliability.

Enhanced electrical performance: The shorter interconnects and reduced capacitance in flexible PCBs lead to improved electrical performance and signal integrity.

Design flexibility: Flexible PCBs allow for creative and innovative product designs that would be challenging to achieve with rigid PCBs.

Flex PCB Assembly Manufacturer

Flexible PCB Assembly

After the flexible PCBs are manufactured, they go through the assembly process to mount electronic components and create functional circuits. The assembly process for flexible PCBs is similar to that of rigid PCBs, with a few additional considerations.

1. Solder Paste Application

Solder paste is applied to the component pads on the flexible PCB using a stencil printing process. The stencil ensures precise and consistent solder paste deposition. Due to the flexible nature of the substrate, additional support may be required during stencil printing to maintain accuracy.

2. Component Placement

Surface mount components are placed onto the solder paste deposits using pick-and-place machines. The machines use vision systems to accurately position the components on the pads. Flexible PCBs may require specialized fixturing to keep the substrate flat and stable during component placement.

3. Reflow Soldering

The assembled flexible PCB is then subjected to a reflow soldering process, where the solder paste is melted to create electrical and mechanical connections between the components and the PCB. Reflow soldering for flexible PCBs requires careful control of the temperature profile to avoid damaging the substrate or components.

4. Inspection and Testing

After reflow soldering, the assembled flexible PCBs undergo visual inspection and electrical testing to ensure proper functionality and quality. Automated optical inspection (AOI) systems and flying probe testers are commonly used for this purpose.

As an integrated solutions provider, our customers experience significant reductions in time-to-market by utilizing our services. The benefits for you include upfront design support, prototyping, supply chain management, and delivery of a fully-tested and assembled finished product that is not only functionally reliable but also delivered reliably (95% on-time delivery).

Our services include:

- Initial design

- Circuit fabrication

- Assembly operation

- Functional testing

We offer turnkey, prototype, pre- and full-rate production of flexible, printed circuit interconnect solutions.

Why Choose China PCBA Supplier KSPCBA as Your Flex PCB Assembly Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108Online Service