* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

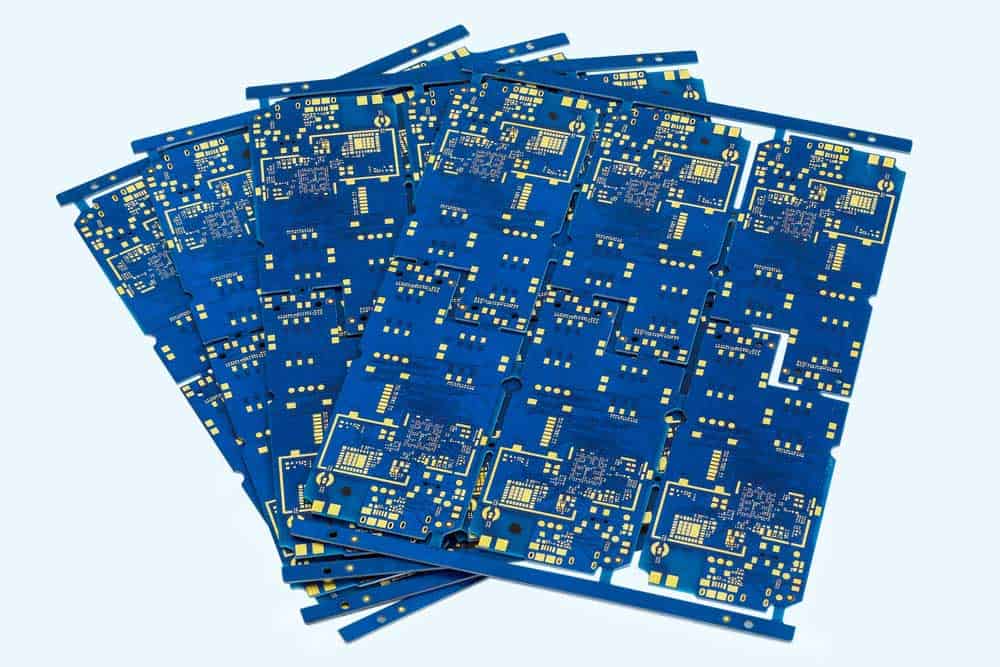

A PCB (Printed Circuit Board) consists of an insulation board as the base material, which is cut to a specific size. It typically includes at least one conductive pattern and various holes (such as component holes, fastening holes, and metallization holes). The PCB serves to replace the chassis of older electronic devices, facilitating the connection between electronic components.

### Selection of Base Materials for PCBs:

1. **Gold Plate**:

The primary issue with this substrate is the "Black Pad" phenomenon, which has led many large manufacturers to avoid using it in lead-free processes. However, most domestic manufacturers still utilize this method.

2. **Silver Plate**:

Silver has strong electrical mobility, which can lead to leakage. However, today's "dipping silver" is not the same as pure metal silver; it is combined with organic materials, making "organic silver." This type can meet the requirements for future lead-free processes and has a longer welding lifespan than OSP boards.

3. **OSP Board**:

The OSP (Organic Solderability Preservative) process is cost-effective and easy to operate, but its popularity is limited due to the need for modifications in assembly plant equipment and processes. After being subjected to high temperatures, the protective film on the PAD can be damaged, reducing solderability. This issue is particularly pronounced during secondary reflow soldering. Consequently, if the process involves a second DIP (Dip Soldering Process), it may face significant welding challenges.

### The Concept and Classification of PCB Substrates

PCBs, also known as printed circuit boards, have been a crucial component in electronic products for over a century. Their design primarily focuses on layout. The main advantage of using PCBs is that they significantly reduce wiring and assembly errors, enhancing automation and increasing production efficiency.

How to choose the base material of PCB board

**What is the Substrate in a PCB? **

Substrates are fundamental in printed circuit board manufacturing. During the production of single and double-sided boards, processes such as hole drilling, electroless copper plating, copper plating, and etching are selectively performed on the substrate material, which is typically copper-coated foil laminate. This process produces the required circuit patterns.

Multi-layer printed boards consist of an inner core of thin copper-clad foil that is bonded with conductive pattern layers and semi-cured sheets through a one-time lamination process, allowing for interconnections across multiple conductive layers. Therefore, the substrate material, whether copper-clad foil or semi-cured sheet, plays an essential role in printed boards. It serves three main functions: conduction, insulation, and support. The performance, quality, processability, manufacturing cost, and manufacturing standard of printed boards are heavily influenced by the choice of substrate material.

### Classification of Copper-Clad Foil

Copper-clad foil can be classified in several ways. Generally, it can be divided into five categories based on the type of reinforcement material used:

- Paper-based

- Glass fiber cloth-based

- Composite materials (CEM series)

- Laminated multi-layer board bases

- Special material bases (ceramic, metal core, etc.)

When classified according to the resin adhesive used, common types of paper-based copper-clad laminates (CCL) include phenolic resin, epoxy resin (FE-3), and polyester resin. The most widely used resin for glass fiber cloth CCL is epoxy resin.

### Types of Substrate Materials

PCB substrate materials are generally classified into two categories: rigid substrate materials and flexible substrate materials.

An important type of rigid substrate material is the copper-clad plate, which is made from reinforcing material impregnated with resin adhesive, dried, cut, and laminated into a blank. This blank is then coated with copper foil and shaped through high-temperature and high-pressure processing in a hot press. Semi-cured sheets used for multi-layer boards are a semi-finished product in the process of copper-clad plate production, primarily consisting of glass fabric impregnated with resin and dried.

This revised text organizes the information clearly while correcting any errors in spelling, grammar, and punctuation.

Why Choose China PCBA Supplier KSPCBA as Your the base material of PCB board Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108