* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

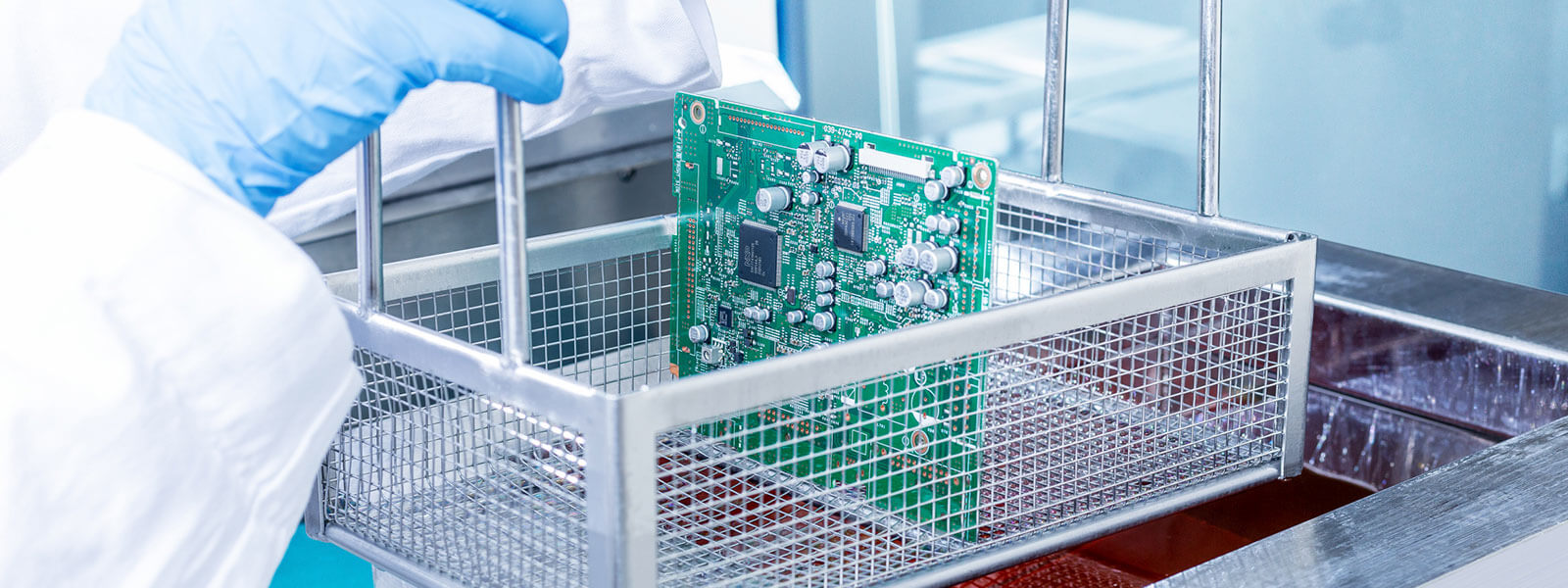

After the completion of the PCBA processing process, residues are often found on the surface of the PCBA. These residues not only affect the appearance but also impact the quality of the PCBA. Therefore, it is crucial to clean the PCBA. In this text, I will introduce two methods of cleaning a PCBA: manual cleaning and automatic cleaning.

Manual cleaning is the preferred method for small and medium-sized PCBA processing plants due to its low cost and effectiveness. The tools required for manual cleaning include cleaning tanks, brushes, spray cans, gloves, IPA or VIGON EFM, deionized water, wipe paper, air guns, and sealed bags.

Here are the steps for manual cleaning:

1. Clean the PCB circuit board with IPA or VIGON EFM. Alternatively, spray IPA and EFM on the surface of the circuit board, using approximately 10 ml per 4 square inches.

2. Use a moist soft short-bristled brush to wipe the circuit board continuously for about 10 seconds.

3. Rinse with deionized water, using about 10 ml per 4 square inches. This step removes any potential pollutant residues.

4. Hold the edge of the circuit board and wipe off the excess deionized water with a clean lint-free wipe.

5. Visually inspect the cleanliness of the PCBA circuit board.

6. If necessary, use an air gun to dry the circuit board.

7. If the circuit board or components need to be stored for some time before coating, put them in a sealed bag containing a desiccant.

How to wash PCBA?

Automatic cleaning is divided into three methods: water cleaning, semi-aqueous cleaning, and solvent cleaning. The tools and materials required for automatic cleaning include a water cleaning machine, a deionized water system, a conductivity tester, a beaker, and deionized water.

Here are the steps for automatic cleaning:

1. Prepare deionized water using an electrodialysis device and an ion exchange resin tank.

2. Test the conductivity of the water after electrodialysis and ion exchange resin tanks using a conductivity tester. If the conductivity meets the index requirements, it can be used for water cleaning.

3. Introduce the deionized water into the water washing machine.

4. Set the parameters of the washing machine: the washing room and rinsing room are set at 60±10 degrees Celsius, and the drying room is set at 60 degrees Celsius to 90 degrees Celsius.

5. Control the chain speed at 50 to 150cm/min.

6. After cleaning the PCBA, store it in an anti-static turnover container. The anti-static turnover container should be clean and dust-free to avoid secondary pollution of the PCBA after cleaning.

Why Choose China PCBA Supplier KSPCBA as Your wash PCBA Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108