* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

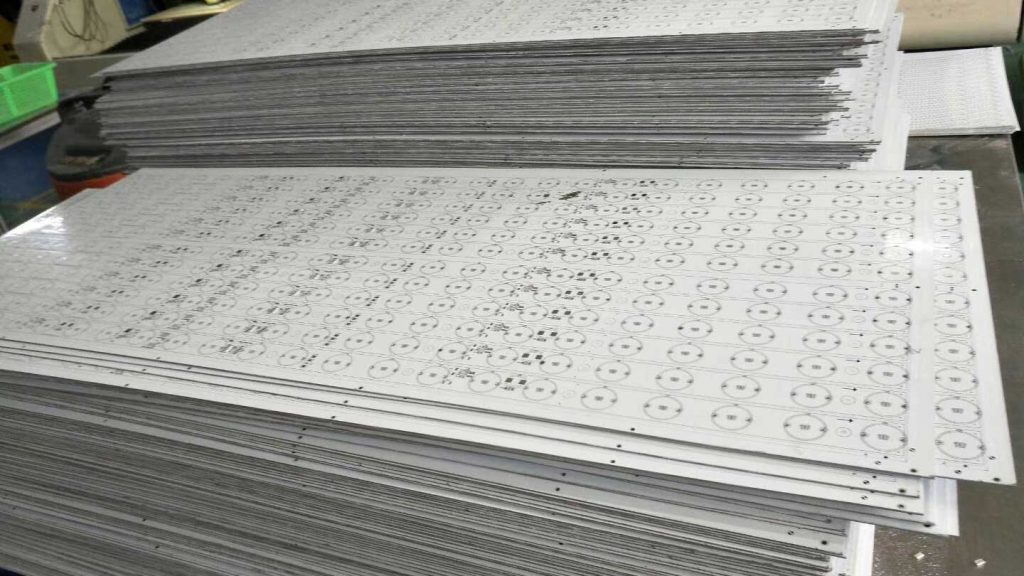

With the rapid development of the electronics industry, electronic products are becoming smaller and smaller, and the power density is increasing. In this context, solving the problem of heat dissipation has become a huge challenge in the design of the electronics industry. However, aluminum substrate has emerged as an efficient solution.

Compared to traditional FR-4 circuit boards, aluminum substrate PCB can reduce thermal resistance to a minimum, have excellent thermal conductivity, but also have excellent mechanical properties.

Construction of aluminum substrate

Aluminum substrate is a copper-clad plate with excellent heat dissipation properties, and its unique three-layer structure includes:

Circuit layer: The power device is mounted on the circuit layer.

Thermal insulation: Heat is transmitted through the insulation to the next layer.

Metal base: Heat is diffused in the metal base and then distributed to the outside of the module to achieve efficient heat dissipation of the device.

This structure makes the aluminum substrate perform well in the field of heat dissipation.

Introduction of Aluminum Substrate PCB

The field of application continues to expand

With the continuous progress of science and technology, the application field of aluminum substrate is also expanding. Here are some examples of aluminum substrate applications:

LED lighting

Aluminum substrate plays a key role in the field of LED lighting. High power LED lighting requires excellent thermal performance, and only aluminum substrates can meet this demand. In every bustling city, the street lights at night are hung high, bright and stable, which cannot be separated from the support of high-heat LED aluminum substrate.

Power supply and motor drive

Power supplies and motor drive systems are extremely demanding for heat dissipation, as they often have to deal with high power densities. The excellent thermal conductivity, mechanical smoothness and consistency of aluminum substrates make them the first choice for these applications.

Communication and computing

In telecommunication, data communication, computer field and office automation equipment, DC/DC converter is an essential component. Due to the limitations of size and power density, it is a wise choice to manufacture converters using aluminum substrates. The excellent thermal conductivity and mechanical properties of the aluminum substrate ensure the efficient operation of the equipment.

Aluminum substrates have become an integral part of the electronics industry, especially in solving the heat dissipation problem of high-power and high-density electronic devices. It has a wide range of applications and plays a key role in improving the performance and reliability of electronic products. In our daily life, the existence of aluminum substrate has long been impossible to ignore. As long as we pay attention, we can find its great role in various fields.

Why Choose China PCBA Supplier KSPCBA as Your Aluminum Substrate PCB Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108