* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

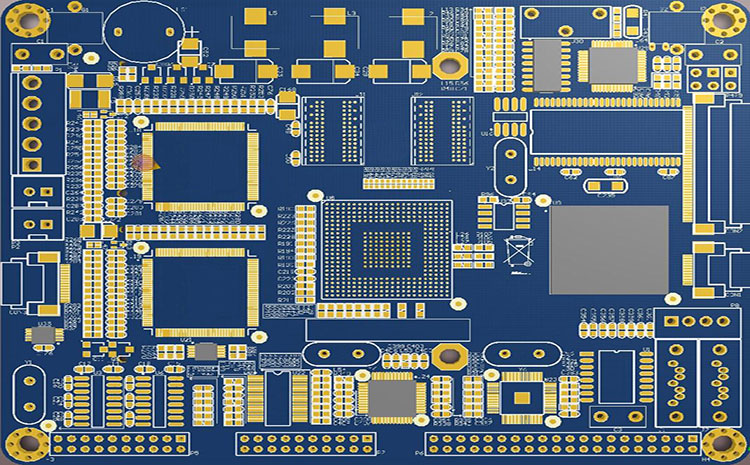

The complexity of electronic products leads to reduced contact distance of integrated circuit components and an increase in signal transmission speed. This, in turn, requires an increase in the number and length of wires, leading to high-density line configuration and micro-hole technology to achieve the goal. To address this, circuit boards become multi-layered, with more power layers and ground planes required as signal lines continue to increase.

To meet electrical requirements for high-speed signals, the board must provide impedance control with AC characteristics, high-frequency transmission capability, and reduce unnecessary radiation (EMI). With the structure of Stripline and Microstrip, multi-layering becomes a necessary design. To reduce the quality of signal transmission, an insulating material with a low dielectric constant and a low attenuation rate is used. To meet the miniaturization and array of electronic component assembly, the circuit board also continuously increases its density to meet the demand.

Introduction to HDI and circuit boards

Micro-hole geometry technology can improve the efficiency of assembly, space utilization, and the miniaturization of electronic products. Circuit board products of this type have many different names in the industry, including SBU (Sequential Build Up Process), MVP (Micro Via Process), and MUM (Build Up Multilayer Board). The common name proposed by the IPC Board Association of the United States is HDI (High Density Interconnection Technology), which is generally referred to as HDI boards or "high-density interconnect technology."

A printed circuit board is a structural element formed by an insulating material supplemented by conductor wiring. Integrated circuits, transistors, diodes, passive components (such as resistors, capacitors, connectors, etc.), and various other electronic components are installed in the final product. By connecting wires, electronic signal connections and organic energy can be formed. Therefore, a printed circuit board is a platform that provides component bonding for receiving the base of the component.

Why Choose China PCBA Supplier KSPCBA as Your Introduction to HDI and circuit boards Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108