* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

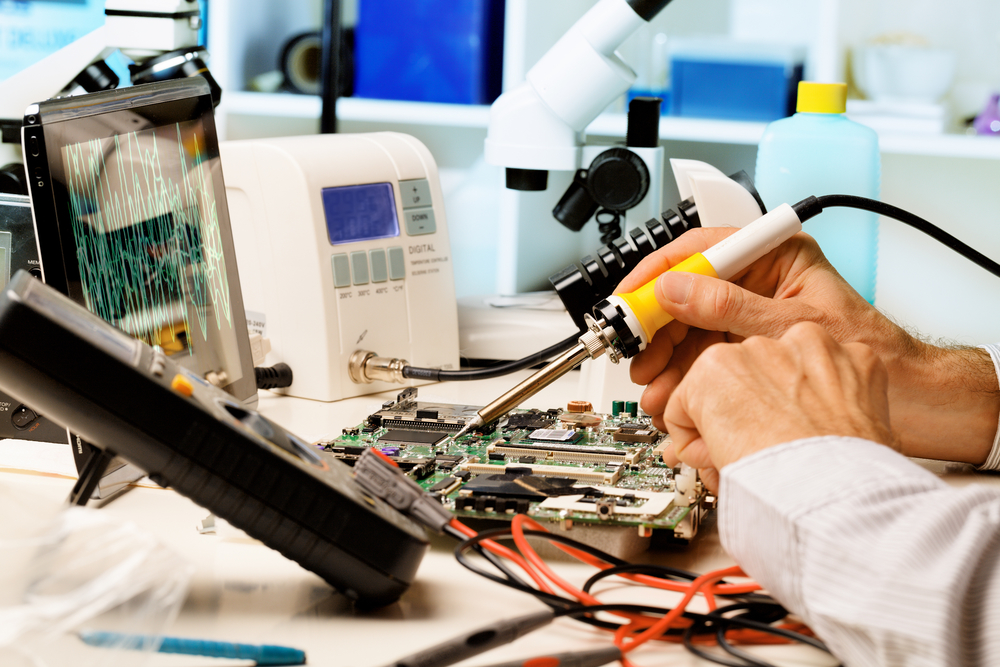

No matter what we do, repairing is a very troublesome thing; and repairing in the electronics industry is bad news for PCBA manufacturers. It also proves that there is a problem with product quality or that it cannot be directly repaired. Products for customers. Then we need to know what conditions need to be repaired. Today, KSPCBA Tech will talk to you about the relevant knowledge points of PCBA repair, including the purpose of the repair process, what are the process requirements for repair, and the precautions for repair.

1. The purpose of PCBA rework process

1. After reflow soldering, there will be some defects in solder joints, such as continuous soldering, virtual soldering, less soldering, and more soldering. It is necessary to remove various solder joint defects after trimming to obtain qualified PCBA solder joints.

2. BGA soldering is poor, and it requires BGA rework station, X-ray, and other auxiliary processing.

3. Replacement of guest-supplied materials that are pasted without inspection.

4. Replacement of components after burning, aging tests, and debugging.

5. Repair of problems that arise after PCBA leaves the factory, during assembly, testing, logistics, and transportation.

Knowledge Points of PCBA Rework

2. Process requirements for PCBA rework

SMT patch factories find repairs time-consuming and labor-intensive, requiring skills and methods to remove the attached devices. Special attention is needed when disassembling SMD devices to prevent damage.

3. Precautions for PCBA rework

1. Do not damage the PCB pads when repairing and disassembling the device to avoid scrapping the entire board.

2. Consider the availability of components for high-reliability products to prevent reliability problems and delays.

3. Maintain the flatness of the component surface and the PCB circuit board panel during repair.

4. Pay attention to potential electrostatic discharge (ESD) hazards.

5. Adjust the temperature curve of reflow soldering and wave soldering after repairing according to the process instructions of the customer's product.

We have shared the purpose of PCBA rework process, the process requirements for PCBA rework, and the precautions for rework. This is the relevant knowledge about PCBA rework that we wanted to share with you. If you have any further questions about rework, feel free to discuss and solve them with us!

Why Choose China PCBA Supplier KSPCBA as Your PCBA Rework Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108