* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

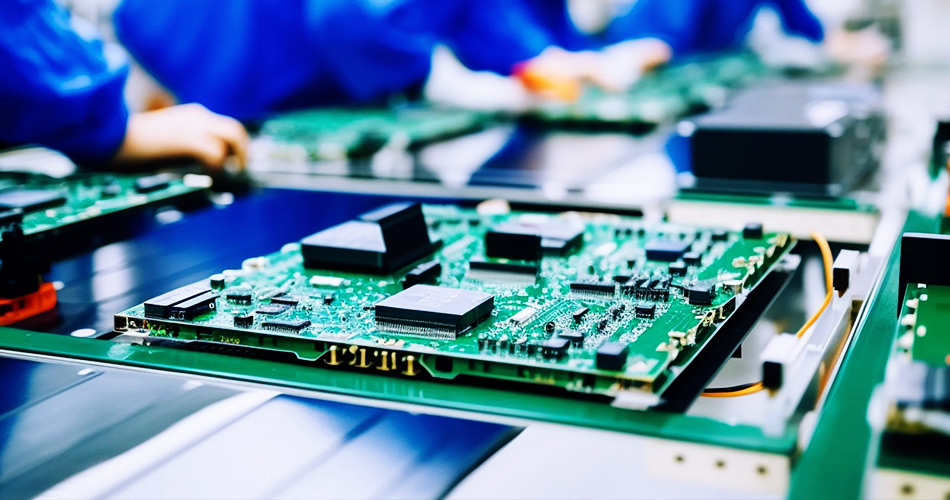

In the process of PCBA welding, the molten liquid filler metal needs to spread over the metal surface so that metal atoms can come into proximity. Therefore, achieving wetting of the weldment’s surface with molten filler metal is a primary requirement for diffusion, dissolution, and the formation of a bonding layer. This aspect is often the most overlooked part of detail control in daily SMT processing.

Achieving Conditions and Influencing Factors of Liquid Solder Wetting in PCBA Welding

1. Wetting Conditions

a. The liquid solder and base metal must have a good affinity for each other, allowing them to dissolve into one another. The mutual solubility between the liquid solder and the base metal is determined by their lattice structures and atomic radii, making wetting an inherent material property.

b. Both the liquid solder and the surface of the base metal must be clean, free from oxide layers and contaminants. A clean surface allows solder to come into close contact with the metal atoms. When there are oxide layers or other impurities between the solder and the metal, they prevent metal atoms from coming together and disrupt the wetting process. This is one reason why false soldering can occur during chip processing.

Liquid Solder Wetting in PCBA Welding

2. Factors Affecting Wetting Power

a. Surface Tension: Surface tension is the phenomenon where a phase interface naturally strives to minimize its surface area due to the different molecular forces at the interface compared to those in the bulk phase. The forces acting on internal molecules of the liquid are symmetrical, causing the net force to cancel out. However, liquid surface molecules are more strongly attracted to other liquid molecules than to atmospheric molecules, leading to a tendency for the liquid surface to shrink to its minimum area. Wetting is the force that enables liquid to spread across a solid surface, while surface tension opposes this wetting force. Since molten solder naturally minimizes its surface area due to surface tension, the wetness of molten solder on a metal surface is closely related to the liquid solder's surface tension.

b. Viscosity: Viscosity is directly related to surface tension—the higher the viscosity, the poorer the fluidity of the solder, which hinders wetting.

c. Alloy Composition: Different alloys and their composition ratios can impact both viscosity and surface tension. Specifically, the viscosity and surface tension of the Sn-Pb alloy vary with the composition of the alloy.

d. Temperature: Increasing the temperature reduces both viscosity and surface tension. This analysis highlights the critical role that liquid solder wetting plays in PCBA welding, emphasizing the need for SMT processing plants to prioritize this detail.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Welding Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108