* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

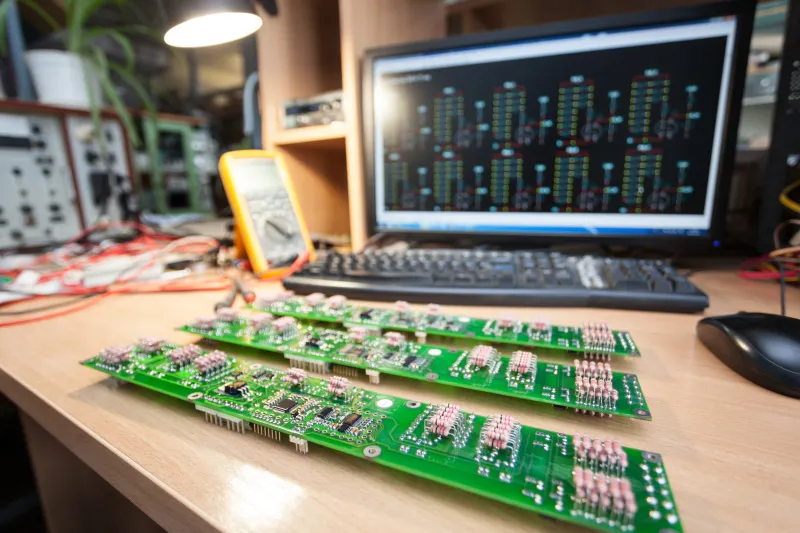

If you want to have a circuit board that can perform multiple functions, you can't achieve it with a bare PCB. The bare board must be mounted, plugged in, and soldered. This step-by-step process is called PCBA.

The PCBA process can be divided into four main stages: SMT patch processing, DIP plug-in processing, PCBA testing, and finished product assembly.

1. SMT Patch Processing

The SMT patch processing involves purchasing components according to the BOM configuration list provided by the customer and confirming the PMC plan for production. After the preparatory work is completed, SMT programming is initiated, a laser stencil is made according to the SMT process, and solder paste printing is done. The components are then mounted on the circuit board using the SMT placement machine, and if necessary, online AOI automatic optical inspection is carried out. After testing, a perfect reflow oven temperature curve is set to allow the circuit board to flow through the reflow soldering. After the necessary IPQC inspection, the DIP plug-in process can be used to pass the plug-in material through the circuit board, and then flow through wave soldering for soldering. The necessary post-furnace process follows. A comprehensive QA inspection is then performed to ensure that the product quality is acceptable.

Main Links in the PCBA Production Process

2. DIP Plug-in Processing

The process of DIP plug-in processing involves plug-in, wave soldering, cutting feet, post-welding processing, washing board, and quality inspection.

3. PCBA Test

PCBA testing is the most critical quality control stage in the entire PCBA processing process. It is necessary to strictly follow the PCBA test standards and test the test points of the circuit board by the customer's test plan (Test Plan). PCBA testing includes five main forms: ICT testing, FCT testing, aging testing, fatigue testing, and testing under harsh environments.

4. Finished Product Assembly

The PCBA board that has passed the test is assembled on the shell and then tested. Finally, it can be shipped.

PCBA production is a series of interdependent stages. Any problem in any of the stages can have a significant impact on the overall quality, and every process needs to be strictly controlled.

The above outlines the four main stages of PCBA production. Each major stage is assisted by numerous minor stages, each of which has one or more test procedures to ensure product quality and prevent the outflow of defective products.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Production Process Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108