* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

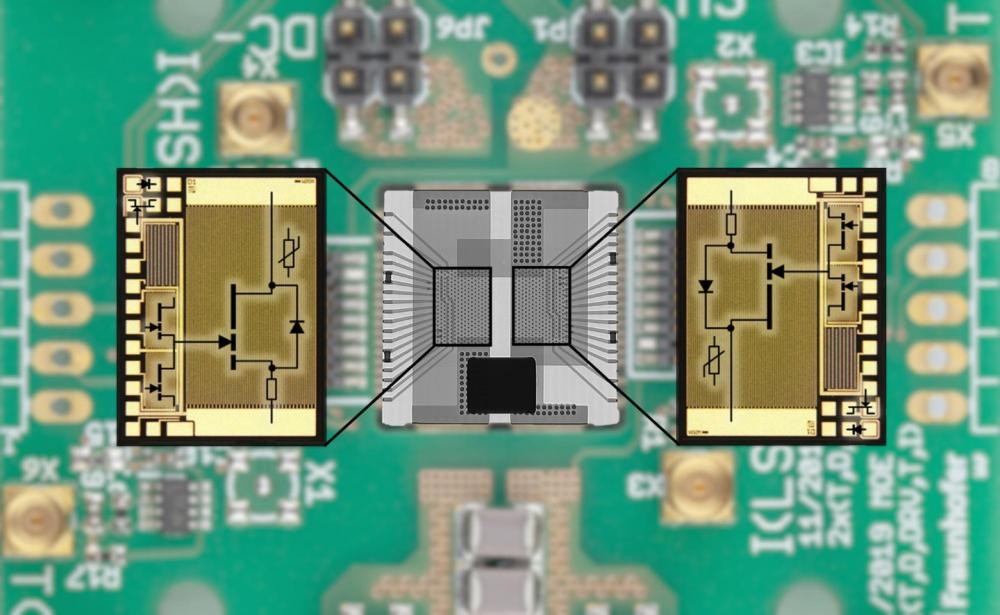

The purpose of modular and system integration technology is to provide optimized and improved solutions for the three primary requirements of LED mounters: speed, accuracy, and flexibility. Flexible modular technology emphasizes portability, interoperability, scalability, and configurability of equipment, allowing for straightforward and efficient construction and completion of surface mount equipment tailored to specific needs, thereby enhancing assembly productivity.

The motor employs a lightweight design concept, significantly reducing the weight of the machine's moving parts. This results in a substantial decrease in power consumption during operation, lowering it to just one-fourth of what typical placement machines consume. Although the LED placement machine does not require high placement accuracy, it does necessitate faster speeds. Currently, several specialized LED mounters in China can be categorized into models with 4, 6, and 8 devices based on their speed capabilities. For a practical understanding, you can refer to the LED640, LED660 V, and LED680 V LED mounters. The number in the middle indicates the number of stickers; a higher number corresponds to a higher speed. The mainstream application of LED placement machines should involve mounting large areas of PCB boards to meet online requirements and ensure speed.

Modularity and System Integration Technology

**Development Trends in LED Chip Machines**

LED mounters play a crucial role in the production and manufacturing process. They represent the largest investment in contemporary electronic assembly technology production equipment and embody the most advanced technologies, significantly influencing the production capacity and efficiency of SMT (Surface Mount Technology) production lines. Most faults and speed bottlenecks primarily arise during the mounting process, making the development of mounting machine equipment particularly noteworthy. The number and sophistication of SMT machines have become key indicators of a company’s, region’s, or country’s electronic manufacturing capabilities.

At present, LED placement machines are progressing toward higher accuracy. The term "accuracy" in this context refers to the mechanical precision of the navigational movements along the X and Y axes, as well as the rotational precision of the Z axis. Chip mounters utilize precision mechatronics technology to control mechanical motions, enabling them to precisely and reliably grab components from feeders and attach them to circuit boards after calibrating the alignment mechanism. One of the primary challenges in producing higher-performance products is to enhance the mounting accuracy of mounters.

In conventional LED packaging technology, the connection between chip electrodes and support pins is typically achieved through gold wire interconnection. However, gold wire fractures are a common cause of failure. Abnormalities in gold wire during LED lighting applications lead to frequent issues such as dead lights and significant light decay. Dead lights can be categorized into two main situations: those that do not shine at all and others that flicker, displaying brightness only when hot or not at all. The primary reason for a light not shining is an open electrical circuit, while flickering typically results from virtual welding or poor contact of the gold wire.

LED gold wire packaging is commonly referred to in the industry as "no package" or "free package." This process utilizes flip chips that are directly surface-mounted onto the circuit board, bypassing the SMD (Surface Mount Device) packaging process. Because the chip area is much smaller than that of SMD devices, this method requires very precise design considerations.

Why Choose China PCBA Supplier KSPCBA as Your Modularity and System Integration Technology Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108