* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

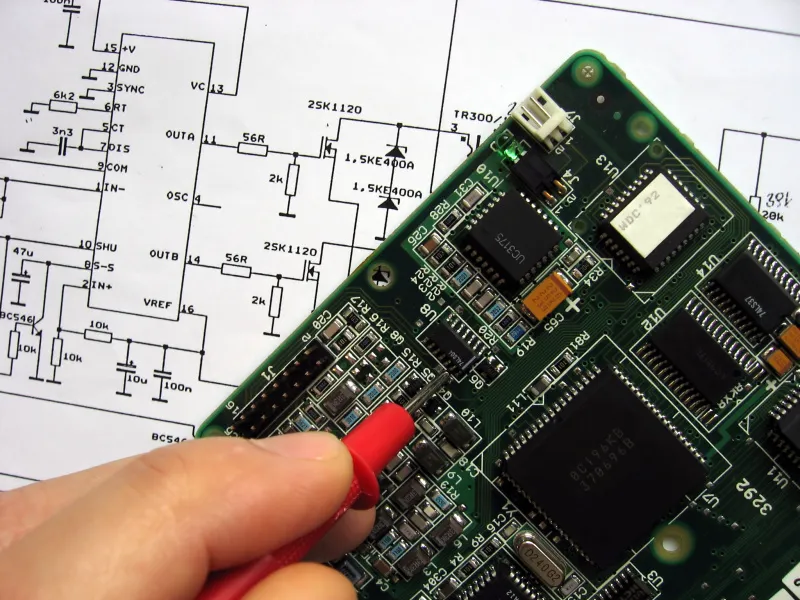

The purpose of electrical testing is to assess PCB dependability in terms of electrical performance. primarily including tests for power frequency response, power factor, voltage withstand, insulation resistance, etc. Potential issues with PCBs, such as improper contact, electrical short circuits, etc., can be found by electrical testing.

When testing printed circuit boards, one of the tests performed is called capacitance testing. This test is conducted to identify short circuits on the board. The process involves charging the power grid and then measuring the induction capacity. Another test performed is the resistance test which measures the resistance in ohms.

What are the contents of PCB assembly electrical testing?

Please find the revised text below. I have made it clearer, fixed any spelling, grammar, and punctuation errors.

1. Resistance Testing

Resistance testing measures the resistance in ohms. Resistance is a measure of the collision between electrons and atoms that hinders the flow of electrons when current flows through a conductor. When testing resistance, low resistance indicates a good conductor. It's essential to consider that the longer the circuit, the thinner the resistance, which is an important factor to take into account during the testing process.

2. Capacitance Testing

Capacitance testing is used to search for short circuits on circuit boards. This process involves charging a network and measuring the sensing capacity.

3. Continuity Testing

Continuity testing is a dependable method that ensures that the resistance between test points does not exceed the necessary or required limits.

4. Comparative Testing

Comparative testing is done using a main control board that has been verified to help teach list programs. It can be used to compare with other boards. However, it's important to note that there may have been defects in the main control board before.

5. Clamshell Testing

Clamshell testing is a popular method that improves reliability by conducting a test on both sides of the circuit board simultaneously. This tests all points on the circuit board at the same time.

6. Flip Testing

Flip testing is an operation that can be performed on either side of the printed circuit board as a universal grid.

7. Adjacency Testing

Adjacency testing performs short circuit testing by checking the isolation between conductors. It can test proximity or line of sight proximity.

8. Flight Probe Testing

Flight probe testing is a reliable method that involves using flight probes to test sequences.This test sequence detects any openings and short circuits throughout the board, making it ideal for high-speed boards.

The importance of electrical testing in the electronic manufacturing industry cannot be overstated. By testing the electrical characteristics of circuit boards, we can ensure the stability and reliability of products, reduce failure rates, and improve production efficiency. Additionally, potential issues in circuit board production can be identified through testing, allowing for timely improvements to be made, ultimately leading to improved product quality and reliability. Furthermore, recording and analyzing test data provides a reference and basis for subsequent product design and production. It is only through scientific and reasonable testing methods that we can ensure the improvement of product quality and customer satisfaction.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108