* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

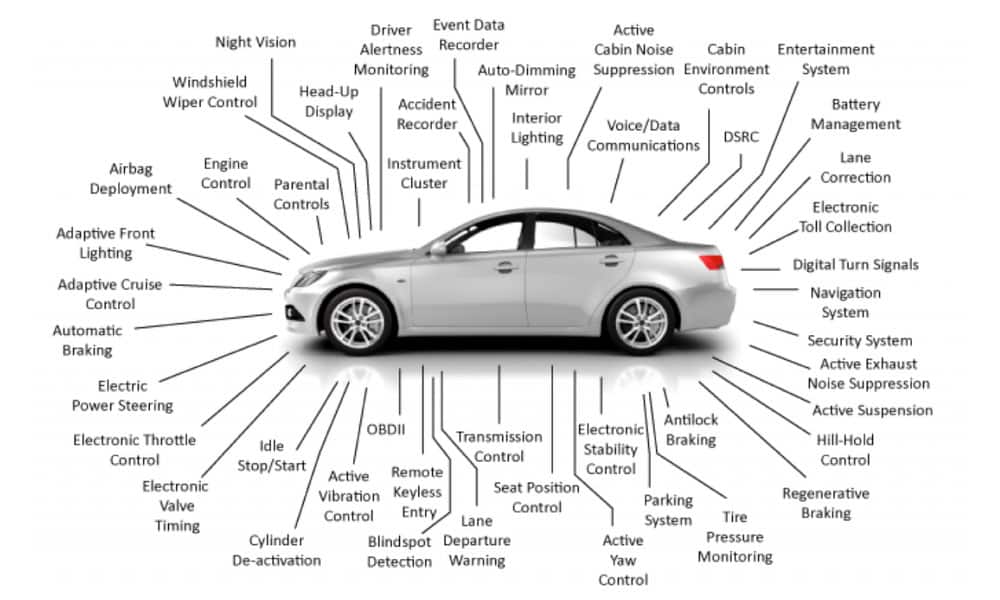

Printed circuit boards (PCBs) have become widespread in modern vehicles. As cars continue to incorporate more electronics for engine control, entertainment, navigation, safety systems, and electric powertrains, PCBs provide the foundation to manage these complex functions.

Automotive PCBs are printed circuit boards specifically designed and manufactured for use in vehicle applications. They serve as the platform to mount components and connect electronic circuits to enable automotive systems and subsystems. Compared to commercial PCBs, auto PCBs require enhanced capabilities to withstand harsh vehicle environments.

The new energy vehicle market has experienced significant growth in recent years. Further advancements in intelligence and electronics also contribute to the growth of the PCB industry. It is estimated that the global automotive electronics output value will have a compound annual growth rate (CAGR) of about 6% from 2019 to 2023, making it the fastest-growing field of PCB products.

New energy automotive vehicles have become the new main battleground for circuit board enterprises. PCBs used in the automotive industry are characterized by high reliability on components, high entry barriers, and a time-consuming certification process. This is why it's important to select experienced and trustworthy automotive PCB manufacturers.

PCB Automotive Manufacturer

Several types of PCBs are designed to withstand automotive environments while meeting functionality needs. Common types include:

- Ceramic PCBs: These use ceramic substrates like aluminum oxide or aluminum nitride, providing electrical insulation even at high temperatures along with thermal conductivity, making them well-suited for high-power automotive electronics.

- HDI PCBs: These incorporate finer lines and spaces, smaller vias, stacked micro vias, and often blind/buried vias, allowing greater component density and trace routing for space-constrained engine control units and infotainment systems.

- High Frequency PCBs: These employ RF materials like PTFE or ceramics for radar systems, collision avoidance, satellite connectivity, and wireless communications demands. Careful impedance control and tuning ensure signal integrity.

- Metal Core PCBs: These provide enhanced thermal conductivity to dissipate heat from high-power components, assuring reliable operation of traction inverters, motor drives, battery pack control, etc.

An experienced automotive PCB manufacturer and assembler brings specialized expertise and production capabilities, including:

- Domain Expertise: A dedicated automotive PCB producer understands the technical demands and standards compliance needs for auto electronics, facilitating design review and tailored material selection for each application.

- Robust Supply Chain: Supplier partnerships allow maintenance of qualified components inventory and consistent materials sourcing essential for rate production, sustaining capacity buffers and guarding against automotive industry volatility.

- Quality Assurance: Rigid quality management, starting from supplier qualification to statistical process controls and extensive testing, instills reliability into automotive PCBs and meets zero-defect expectations.

With over 10 years in the PCB industry, we have garnered in-depth knowledge across automotive PCB design, fabrication, component sourcing, quality control, and responsive customer service.

Why Choose China PCBA Supplier KSPCBA as Your PCB Automotive Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108