* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

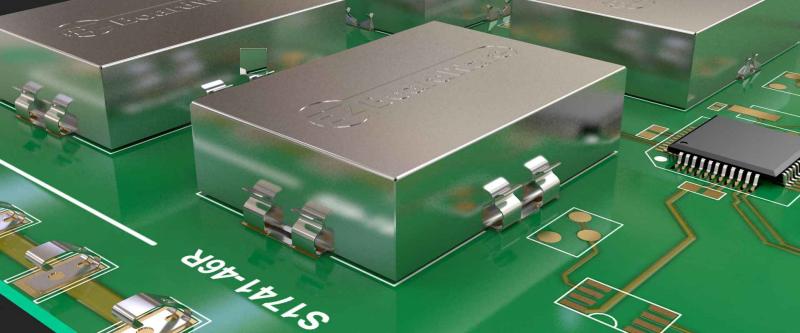

Electromagnetic shielding in PCB boards involves using metal components to control the propagation of electric fields, magnetic fields, and electromagnetic waves between different areas. This is achieved by enclosing interference sources with a shielding body to prevent electromagnetic interference from affecting nearby components.

It is a common misconception that simply enclosing components in a metal box and grounding it will provide effective electromagnetic shielding. In reality, the effectiveness of electromagnetic shielding depends on two key factors: the shield's entire surface must be conductive and continuous, and there should be no direct penetration of conductors through the shield. Conductive discontinuities, such as non-conductive gaps, can lead to electromagnetic leakage, similar to how fluid can leak from a container. These gaps can be filled with a conductive elastic material, known as an electromagnetic sealing gasket, to prevent leakage.

PCB Board Shield

Some literature compares electromagnetic shielding to a watertight container, suggesting that sealing gaps with a conductive elastic material will prevent electromagnetic leakage. However, whether a gap or hole will leak electromagnetic waves depends on the size of the gap relative to the wavelength of the electromagnetic wave. At high frequencies, where wavelengths are short, electromagnetic sealing gaskets are necessary.

Types of electromagnetic sealing gaskets include conductive rubber, metal braided mesh, finger reeds, and multiple conductive rubbers. These materials vary in their properties, such as conductivity and elasticity. When choosing the type of electromagnetic sealing gasket to use, factors to consider include shielding effectiveness requirements, environmental sealing requirements, installation structure requirements, and cost requirements on the PCB board.

Why Choose China PCBA Supplier KSPCBA as Your PCB Board Shield Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108