* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

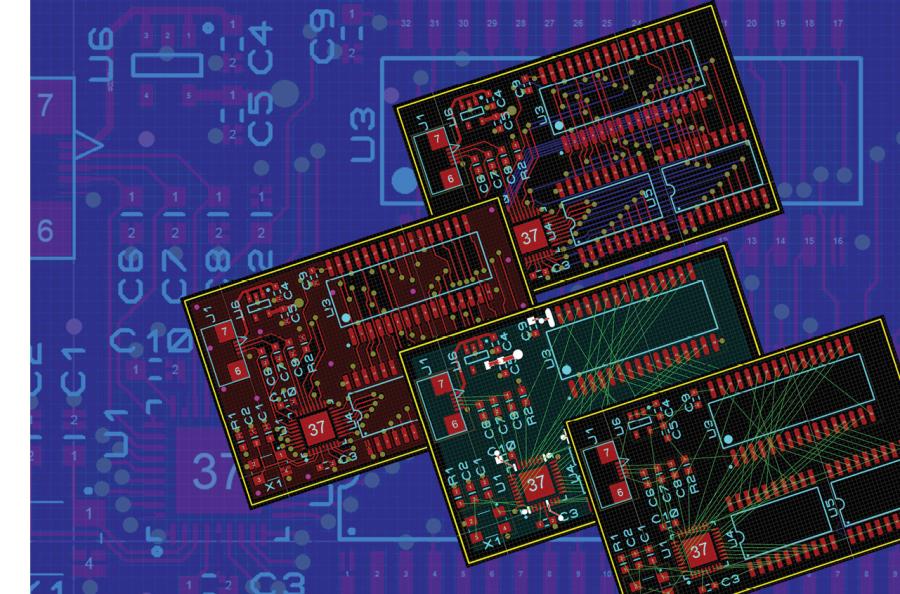

An automatic LED placement machine is a high-precision automation device controlled by a computer. It is composed of a frame, PCB transmission mechanism, bearing assembly, drive and servo positioning system, mounting head, feeder, optical identification system, sensors, and a computer control system. The machine efficiently performs functions such as suction, displacement, positioning, and placement, quickly and accurately mounting SMDs onto PCB boards.

### Differences Between LED Mounters and Traditional Mounters

LED mounters must meet specific mounting accuracy requirements for lamp beads, including sizes 3014, 2835, 3528, 5050, 5630, and 5730. Compared to traditional mounters, LED mounters have lower accuracy requirements but emphasize performance aspects, such as stability, speed, operability, and size. Therefore, LED placement machines must adhere to certain design principles and requirements:

1. **Intelligent Technology:** LED-specific mounters utilize advanced sensors that effectively gather data during operations, ensuring the stability and reliability of the entire mounting process. Regular maintenance, including cleaning the machine's surface and circuit board, is essential to prevent overheating caused by dust accumulation. Good stability in LED mounters helps maximize production efficiency and reduce costs for enterprises.

2. **Speed Requirements:** The LED placement machine should have a minimum installation speed of 18,000 points per hour.

3. **User-Friendly Operation:** Implementing a simple and intuitive operation method can significantly reduce personnel training time and minimize operational errors during production, ultimately improving efficiency and product quality.

4. **PCB Length Capacity:** The LED placement machine must accommodate PCB lengths of at least 1.2 meters, as many LED applications involve replacing traditional lighting tubes, which often exceed standard PCB dimensions. Additionally, to avoid color differences in single LED lamp boards, all LED lamp beads in a batch must have the same color temperature BIN. The term "BIN" refers to ranges of parameters for LED lamp beads, which may include voltage, color temperature, and brightness.

PCB transfer mechanism and bearing organization

### Development Status of Domestic LED Placement Machine Technology

As the fourth-generation light source market continues to expand, and with strong support from government policies, the domestic LED lighting industry has experienced rapid development. The sector has shifted from a focus on LED displays to a broader application in commercial lighting, indoor and outdoor lighting, and lighting engineering.

The LED-related equipment industry is growing robustly, including advancements in reflow welding, wave soldering, printing presses, LED placement machines, and LED packaging equipment. Currently, most domestic LED equipment consists of small mounters capable of handling 1.2-meter light boards, primarily using a platform motion structure combined with a double swing arm movement mode for LED mounting. Track-type LED placement machines are relatively rare in China, representing an area for future development among many companies.

Currently, domestic LED chip technology is still in its infancy, with products mainly addressing the early needs of small and medium-sized enterprises. As China is a major player in electronic manufacturing, there is a demand for various grades of domestic LED placement machines. It is crucial to optimize designs according to actual market needs to reduce the developmental challenges faced in the production of domestic LED mounters and to facilitate quicker integration into the electronic equipment industry.

Why Choose China PCBA Supplier KSPCBA as Your PCB transfer mechanism and bearing organization Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108