* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

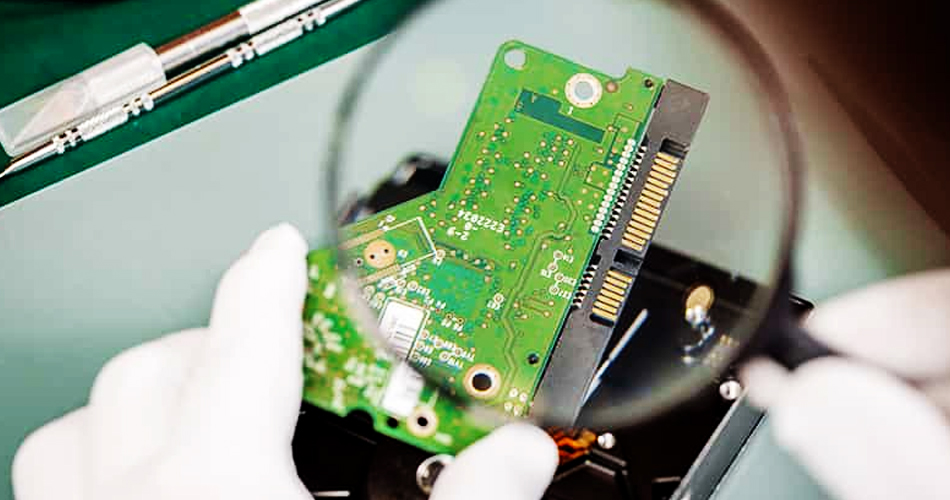

As electronic products become increasingly miniaturized and components are assembled more densely on circuit boards, SMT (Surface Mount Technology) production and inspection face significant challenges. Various testing methods have emerged to address these challenges, including manual visual inspection, digital microscopy, SPI (Solder Paste Inspection), automatic optical inspection (AOI), SMT first article testing, online testing (commonly referred to as ICT or In-Circuit Testing), functional testing (FCT), and automatic X-ray inspection (AXI). Below is a brief introduction to the main SMT testing technologies:

1. SPI Solder Paste Detector: The SPI solder paste detector employs optical principles to determine the height of solder paste printed on a PCB using triangulation. Its primary function is to evaluate and analyze the quality of solder paste printing, helping to identify SMT process defects early on. This allows users to monitor production issues in real time, reduce defects caused by inadequate solder paste application, support quality control, and improve overall process performance.

2. SMT First Article Detector: The SMT first article detector integrates CAD coordinates, BOM (Bill of Materials) lists, and the first article PCB scanning map for automatic data collection. This system simplifies the first article inspection for SMT production lines. It automatically matches LCR (inductance, capacitance, resistance) readings to their corresponding positions and assesses the results, which minimizes false negatives and missed tests. Additionally, it generates test reports that are stored in a database.

PCBA Factory Inspection Technology

3. X-Ray Testing (AXI): Automatic X-ray inspection (AXI) utilizes X-rays' ability to penetrate materials to locate internal defects within solder joints, particularly those associated with BGA (Ball Grid Array), CSP (Chip Scale Package), and FC (Flip Chip) solder joints. X-ray inspection can reveal various solder joint quality issues such as open circuits, short circuits, voids, and insufficient solder, providing quantitative analysis. Its key advantage is the capability to inspect solder joints beneath BGA packages, identifying issues like bridging, open circuits, missing solder balls, displacement, and poor joint definition.

4. ICT Online Tester: The ICT online tester checks for manufacturing defects and faulty components by assessing the electrical performance and connectivity of components on the circuit board. Using a specialized needle bed, it makes contact with the soldered points of components to perform tests with test voltages in the hundreds of millivolts and currents up to 10 milliamperes. This method accurately detects faults such as missing or incorrectly installed components, parameter deviations, and issues related to open and short circuits for various components, including resistors, inductors, capacitors, diodes, silicon controlled rectifiers, field effect transistors, and integrated circuits.

5. FCT Functional Tester: Functional Circuit Testing (FCT) simulates an operating environment to verify the functional state of a circuit board. This testing method involves connecting a special circuit board to the appropriate circuitry of an assembled electronic device and applying voltage. If the device operates normally, the circuit board is considered qualified.

The methods outlined above represent a combined testing approach used for complex PCBs. The specific testing method deployed will depend on the unique conditions of the SMT production line and the assembly density of the surface-mounted components.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Factory Inspection Technology Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108