* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

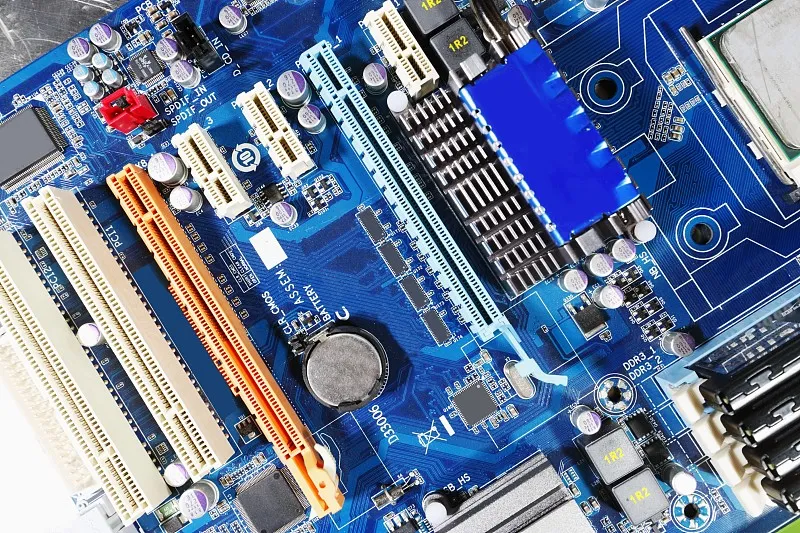

During the PCBA patch processing, the quality control links are highly complex. Each inspection link is crucial to the quality of the final product, which is directly related to the reputation of the manufacturer. Therefore, each link needs to be carefully examined. In this article, we will be discussing the content of the PCBA processing quality agreement.

1. PCB Circuit Board Manufacturing

Upon receiving the PCBA instruction, the Gerber file needs to be analyzed. It is crucial to pay attention to the relationship between the PCB hole spacing and the board's load-bearing capacity to avoid bending or breakage. Wiring must consider key factors such as high-frequency signal interference and impedance.

2. Procurement and Inspection of Components

Component procurement requires strict control of channels. Top-notch PCB manufacturers source components from large traders and original factories to avoid second-hand materials and counterfeit products. A special purchase inspection post must be set up to strictly inspect the components and ensure they are free of faults.

PCBA Processing Quality Agreement

3. SMT Assembly Processing

The temperature control of solder paste printing and reflow oven is a crucial factor. A laser steel mesh of good quality that meets the process requirements must be used. Steel mesh holes may be added or reduced, or U-shaped holes may be used to make steel mesh according to the PCB's requirements. The furnace temperature and speed control of reflow soldering are critical to solder paste infiltration and soldering reliability. AOI testing must be implemented strictly to minimize the adverse effects caused by human factors.

4. DIP Plug-in Processing

The mold design for wave soldering is a key point in the plug-in process. PE engineers must practice and summarize experience to maximize the probability of good products after the furnace.

5. Program Firing

It is recommended to set some test points on the PCB to test the continuity of the PCB and PCBA circuit after soldering all the components. If possible, the customer can provide a program, and burn the program into the main control IC through a burner (such as st-link, j-link, etc.) to test the functional integrity of the entire PCBA.

6. PCBA Board Test

For orders with PCBA test requirements, the main test content includes ICT (In Circuit Test), FCT (Function Test), BurnInTest (aging test), temperature and humidity test, drop test, etc. The customer's test plan operation and summary report data should be followed.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Processing Quality Agreement Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108