* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

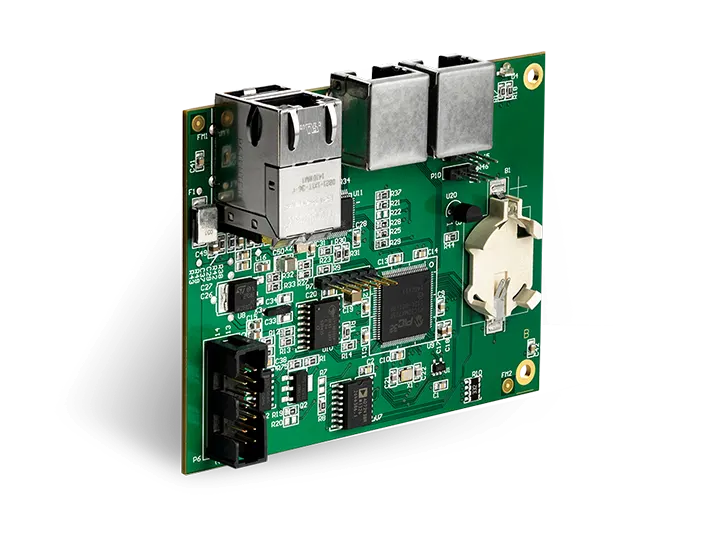

The Printed Circuit Board Assembly (PCBA) processing supply chain covers a number of operational links from component procurement, circuit board production, patch processing, plug-in, program firing, PCBA testing to packaging logistics. In this huge supply chain, the PCBA welding standard inspection of product quality has always been a complex issue. In particular, the IPC electronic acceptance standard IPC-A-610E, which is widely used in the industry, although it provides detailed PCBA pre-factory standards, due to its large and detailed content, for ordinary factories, it may lead to great labor costs and challenges to production efficiency.

1. ICT or functional test passed the standard

The ultimate goal of PCBA welding standard inspection is to ensure that each PCBA board passes inspection before leaving the factory. Among them, one of the most widely used inspection methods is ICT (In-Circuit Test) line detection. By using a simple ICT test stand, a 100% circuit connectivity test can be performed on a manufactured PCBA board. Through ICT testing, PCBA boards can be considered as finished products in 90% of cases.

2. Appearance standard

Each PCBA factory has an Outgoing Quality Assurance (OQA) inspection position, which is responsible for the inspection of PCBA boards before they leave the factory. These inspectors carefully examine the appearance of the PCBA board to ensure that there are no obvious reliability issues, such as insufficient solder thickness or damaged components.

PCBA Welding Standard

3. Aging standard

To ensure the quality of PCBA boards, it is necessary to perform an aging test. Typically, this involves frequent on-off or prolonged power-on operations, which are based on the PCBA board firing procedure. In addition, professional instruments can also be used to detect electromagnetic compatibility, power supply/voltage input and output signal stability. Although this test is more time-consuming, it still requires some degree of sampling. Of course, at the request of the customer, more stringent aging testing may be required, which requires the active cooperation of the PCBA processing plant.

Combine simplicity with experience

IPC standards are an important reference for PCBA welding standards, but in actual production, technicians need to adapt to the situation and flexibly use these standards. Sometimes, IPC standards are significantly lower than the customer's requirements, so moderate adjustments need to be made according to customer needs. In actual operation, experience also plays a key role, and craftspeople need to rely on rich experience to ensure the straight-through rate of the PCBA board.

Through the efficient inspection of the main links, PCBA processing plants can achieve the production of high-quality products, while improving production efficiency and ensuring the smooth operation of the supply chain.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Welding Standard Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108