* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

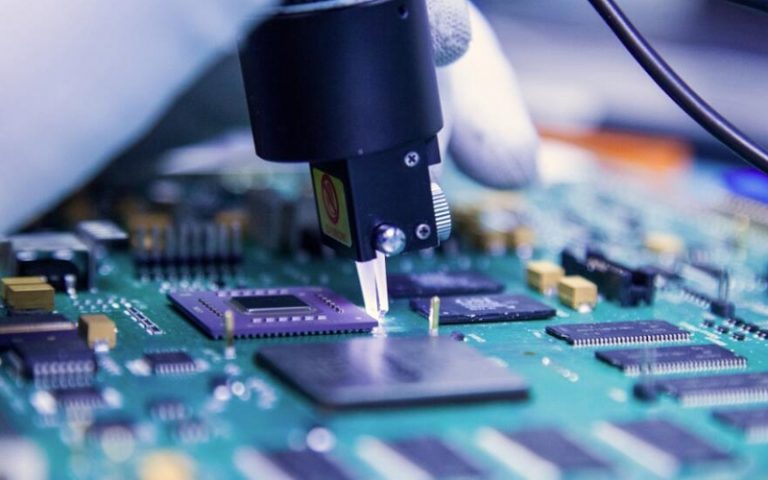

The performance testing of PCBA (Printed Circuit Board Assembly) is essential to ensure the stability and reliability of product performance after PCBA processing. Depending on the actual usage environment and intended purpose of the product, the testing is generally categorized into several types, including:

- Withstand Voltage Test

- Insulation Test

- Salt Spray Test

- Impedance Test

- Vibration Test

- High Temperature and Humidity Test

- Welding Strength Thrust Test

Below is a detailed introduction to these performance tests for PCBA circuit boards.

1. Withstand Voltage Test

The purpose of the withstand voltage test is to assess the voltage capability of the circuit board. The equipment required is a "withstand voltage tester."

Test Method: Connect the PCBA circuit board to the tester. Gradually increase the voltage to 500V DC at a rate not exceeding 100V/S and maintain this voltage for more than 30 seconds. If no faults occur in the circuit, the test is considered passed.

2. Leakage Current Test

The leakage current test checks whether the leakage current of the circuit board meets specified requirements. The necessary equipment is a "leakage current tester."

Test Method: Simulate the leakage current between accessible parts of the product and the two power supply terminals under normal working conditions and standard temperature. If the measured current remains below the design standard, the test passes.

3. Salt Spray Test

The salt spray test examines the corrosion resistance of the circuit board. The required equipment is a "salt water spray tester."

Test Method: Prepare a salt solution using chemically pure sodium chloride and distilled or deionized water with a resistivity of no less than 5000 ohms * CM. Mix 5% sodium chloride with 95% water to create a solution with 5 ± 1% sodium chloride content. Spray the solution continuously for 48 hours at a temperature of 35°C. The average spray amount must reach 80CM²/10CM³ per hour. If the product functions normally and exhibits no visible damage after 48 hours, the test passes.

Performance Test of Common PCBA Circuit Boards

4. Impedance Test

The impedance test evaluates whether the circuit board can operate normally. The required equipment is an "ohmmeter."

Test Method: Connect the transmission line of the circuit board to the battery. Measure the impedance promptly to obtain the "surge" or characteristic impedance. If a longer waiting time is allowed, observe the changes in impedance. Eventually, the impedance value should stabilize at a limit value. If this limit value remains within the specified range, the test is considered passed.

5. Vibration Test

The vibration test assesses whether the circuit board can withstand random vibrations at different levels. The needed equipment is a "vibration meter."

Test Method: Secure the circuit board on the test bench and set the frequency to 20Hz. Perform vibrations along the X, Y, and Z axes for one hour each, totaling three hours. After the test, if the circuit board functions normally, without any abnormal signs such as loose solder joints or component cracking, the test passes.

6. High Temperature and Humidity Test

This test checks the circuit board's performance under extreme high temperature and humidity conditions. The required equipment is a "constant temperature and humidity test chamber."

7. Welding Strength Thrust Test

The welding strength thrust test is conducted to ensure that the welding strength of components adheres to established standards. The required equipment is a "thrust meter."

Test Method: Place the welded PCBA circuit board on the thrust meter. Different specifications of components have varying acceptance criteria. Typically, components located at the edges of the target component should be removed before resetting the instrument to zero. Conduct the thrust test at an angle of ≤ 30 degrees to assess solder strength and record the soldering values.

These seven performance testing methods are essential for PCBA circuit boards. Select the appropriate testing methods based on the specific requirements of your product.

Why Choose China PCBA Supplier KSPCBA as Your Performance Test of Common PCBA Circuit Boards Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108