* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

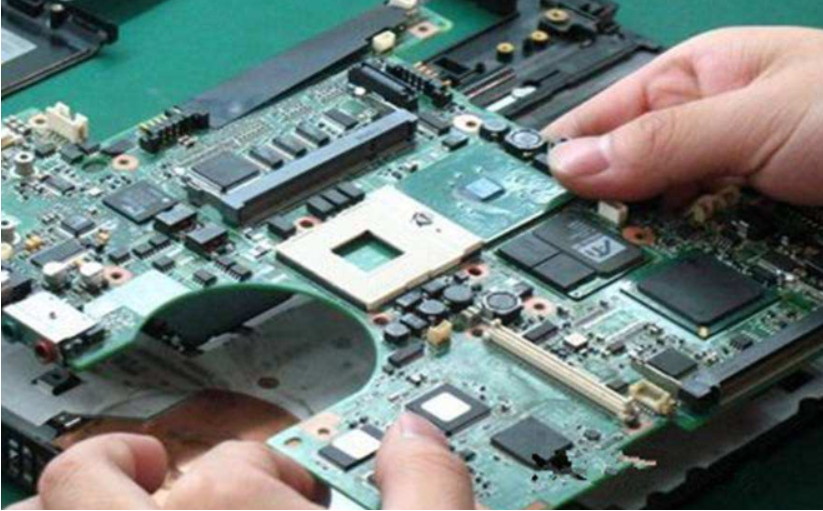

Many friends may not know what production materials are needed for PCBA processing, which can lead to repeated data confirmation and affect project progress. This article introduces the production methods required for PCBA processing.

**Production Materials Required for PCBA Processing:**

1. **PCB Gerber File:** A layered file that defines each circuit layer, bonding pad, screen printing, and other information used to manufacture PCB bare boards.

2. **BOM (Bill of Materials):** An electronic component list that includes component model, brand, description, location number, and consumption information.

3. **MCU Program:** This refers to the chip program burned into the MCU, typically in encrypted hexadecimal or binary format, used to drive the entire PCBA logic operation and control functions.

4. **Test Documents:** These documents define the distribution of test points, steps for testing, and methods for diagnosing common faults.

5. **Upper Computer Software:** Software installed on a computer that initiates the functional item detection of the PCBA.

6. **SMT Coordinate File:** Exported from PCB design software, this defines the coordinate positions of each component on the PCB to facilitate the reading and execution by the SMT mounter.

7. **Other Design Documents:** Such as CAD drawings, PCB schematics, and special engineering process requirements that define post-welding effect drawings.

Production Means Required For PCBA Processing

**PCBA Processing Capabilities:**

1. **Maximum Board Size:** 310mm x 410mm (SMT).

2. **Maximum Board Thickness:** 3mm.

3. **Minimum Board Thickness:** 0.5mm.

4. **Minimum Chip Size:** 0201 package or parts with a diameter greater than 0.6mm x 0.3mm.

5. **Maximum Weight of Mounted Parts:** 150g.

6. **Maximum Height of Parts:** 25mm.

7. **Maximum Size of Parts:** 150mm x 150mm.

8. **Minimum Pin Spacing:** 0.3mm.

9. **Minimum BGA Spacing:** 0.3mm.

10. **Minimum Ball Diameter of BGA:** 0.3mm.

11. **Maximum Element Installation Accuracy (100 QFP):** 25µm @ IPC.

12. **SMT Capacity:** 3-4 million points per day.

**PCBA Processing Flow:**

1. **Customer Orders:** Customers place orders with the PCBA processing plant based on their needs and specific requirements. The processing factory evaluates its capability to complete the order and negotiates production details if confident.

2. **Production Materials Provided by Customers:** After deciding to place an order, customers must provide essential documents and lists to the PCBA processing plant, such as PCB electronic documents, coordinate files, and BOM lists.

3. **Purchase of Raw Materials:** The PCBA processing plant purchases relevant raw materials from designated suppliers according to the documents provided by the customer.

4. **Incoming Inspection:** All raw materials must undergo strict inspection before PCBA processing to ensure they meet quality standards.

5. **PCBA Production:** During processing, the manufacturer must carefully control the furnace temperature to ensure production quality.

6. **PCBA Testing:** The PCBA processing plant conducts rigorous testing to ensure product quality, and the tested PCBs are then delivered to the customer.

7. **After Sales Packaging:** Once processing is complete, the product is packaged and handed over to the customer, finalizing the PCBA processing.

This article describes the essential production methods and procedures required by the PCBA processing plant throughout the processing and production phases.

Why Choose China PCBA Supplier KSPCBA as Your Production Means Required For PCBA Processing Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108