* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCBA | About Us | News | Contact Us

It's important to understand that even if the PCB board's wiring is completed well, the inconsistency of the power supply and the ground line can cause interference that degrades the product's performance and even affects the success rate. Therefore, it's crucial to take the wiring of electricity and ground wire seriously and minimize the noise interference generated by them to ensure the product's quality. Every engineering engineer engaged in designing electronic products must understand the reason for the noise between the ground and the power line.

Here are some things to consider when wiring PCB boards:

1. Co-processing of digital circuits and analog circuits

Many PCBs now include a mixture of digital and analog circuits. Therefore, it's necessary to consider their mutual interference when wiring, especially the noise interference on the ground. The frequency of the digital circuit is high, and the sensitivity of the analog circuit is strong. For the signal line, it's best to keep the high-frequency signal line as far as possible away from the sensitive analog circuit device. For the ground line, it's important to handle the processing and the common ground inside the PCB since the whole human PCB has only one node to the outside. The digital ground and the analog ground inside the board are separated from each other, but only at the interface where the PCB is connected to the outside (such as a plug). The digital ground is slightly shorted to the analog ground, but there is only one connection point. Also, note that there is no common ground on the PCB, which the system design determines.

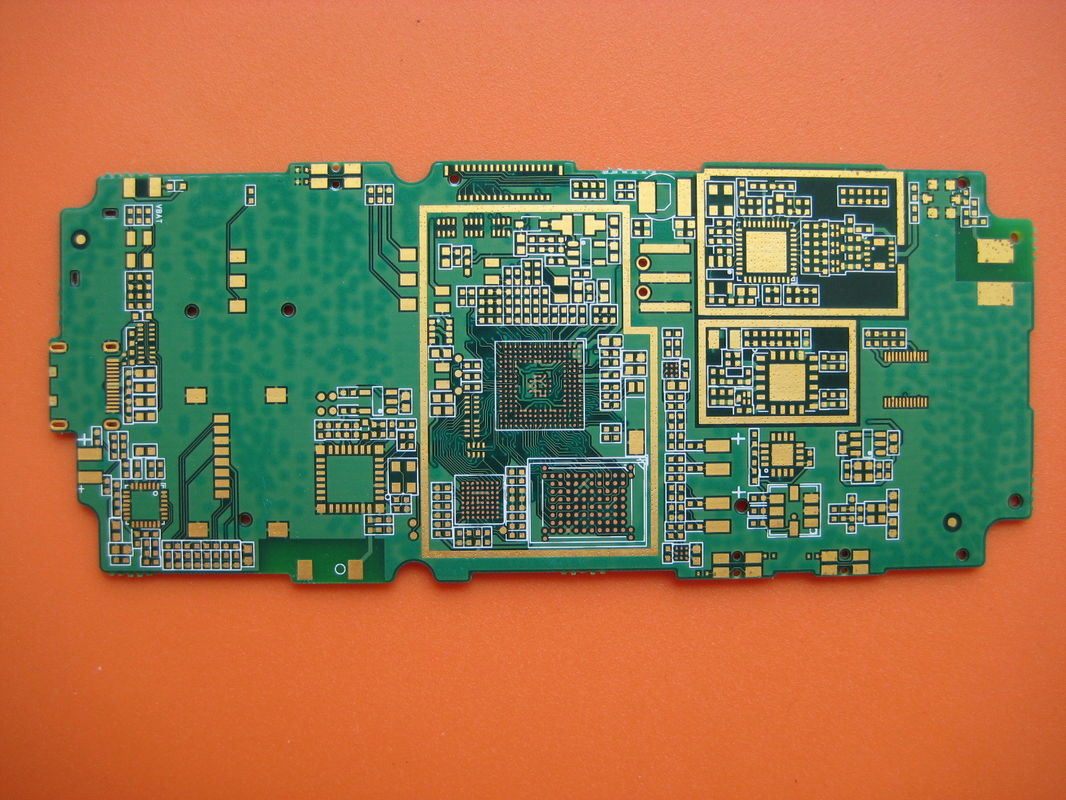

Several Issues With Mobile Phone PCB Design

2. The signal wire is placed on the electrical (ground) layer.

In the wiring of multi-layer PCBs, there aren't many lines left in the signal line layer. Adding layers will cause waste and increase production workload, and costs will increase accordingly. To resolve this contradiction, consider wiring on the electrical (ground) layer. The power layer should be considered first, followed by the ground layer since it's best to preserve the integrity of the formation.

3. Treatment of connecting legs in large-area conductors

In a large area of grounding (electricity), the legs of common components are connected to them, and the treatment of the connecting legs needs to be comprehensively considered. The pads of the component legs are perfectly connected with the copper surface in terms of electrical performance, but there are some hidden dangers in the soldering assembly of the components. For example, it requires a high-power heater and is easy to cause a virtual solder joint. Therefore, taking into account the electrical performance and process needs, making a cross-shaped pad, called a heat shield, commonly known as a thermal pad (Thermal), can greatly reduce the possibility of creating a solder joint due to the cross-distribution heat during soldering. The treatment of the grounding (ground) leg of the multilayer board is the same.

4. The role of the network system in the wiring

In many CAD systems, cabling is determined by the network system. The mesh is too dense, although the path is increased, the stepping is too small, the data volume of the field is too large, which inevitably has higher requirements on the storage space of the device, and the computing speed of the object computer electronic product is also greatly impacted. Some of the paths are invalid, such as occupied by the pads of the component legs or occupied by the mounting holes and the holes. The grid is too sparse, and too few paths have a great impact on the routing rate. Therefore, there must be a sparse and reasonable grid system to support the wiring. The distance between the legs of the standard components is 0.1 inches (2.54mm), so the basis of the grid system is generally set to 0.1 inches (2.54 mm) or less than 0.1 inches of multiples, such as 0.05 inches, 0.025 inches, 0.02 Inches, and so on.

Why Choose China PCBA Supplier KSPCBA as Your Mobile Phone PCB Design Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108