* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

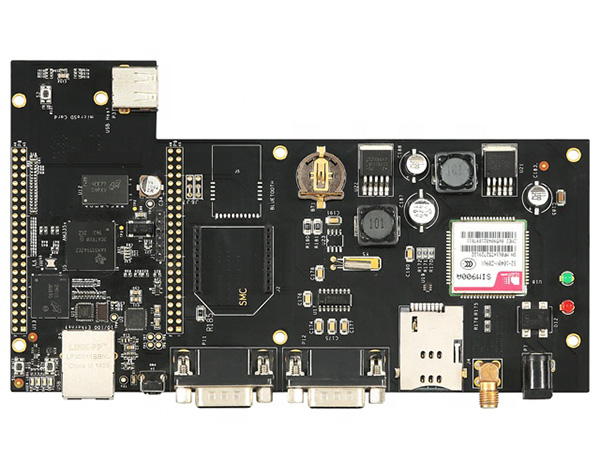

A smart door lock is an advanced version of traditional mechanical locks, designed to enhance user safety, identification, and management. These locks are key components in access control systems. There are four types of printed circuit boards (PCBs) used in smart door locks: internal items, external items, switch items, and antenna housings. All of these PCBs are made from FR-4 material and feature a lead-free spray tin surface treatment, a green solder mask, and white silk screen printing. The internal PCB is a four-layer board with blind holes and measures 150mm by 180mm. The external PCBs are similar in size and shape but do not have blind holes.

For the internal printed circuit boards, in addition to assembling the necessary components, springs, coils, and flat components must also be soldered in. This process involves both horizontal welding and angle protection. Once all four types of PCBs have their components assembled, they must be connected with wires. Three types of wires are used: two-needle, three-needle, and ten-needle. Each wire is color-coded to help customers easily identify the ends of the same wire.

To secure the wires, heat shrink tubing is applied over them. It is important to maintain the same distance between the ends of each wire, and the tightness of the heat shrinkable tubing must be just right: if it is too tight, it may damage the wires, while if it is too loose, it will not secure the wires effectively. Finally, the four types of PCBs are connected using the finished wires.

Smart Door Lock PCB Assembly

Smart door lock PCB assembly technology:

Using battery wave induction technology, the induction is more sensitive.

Main chip of circuit board: Texas Instruments TI chip;

Power supply: 4 AA alkaline batteries;

Static power consumption: <30 microns;

Dynamic power consumption: about 200mA;

Low voltage prompt: 5V;

Induction distance: 3-5cm;

Applicable temperature: -20℃~50℃;

Relative humidity: <95%RH;

Anti-static: >15000v, it can still ensure that information is not lost under strong electrostatic interference, and the work is stable

Smart door lock PCB assembly performance parameters:

Copper Thickness: 1 oz

Substrate: FR4

Maximum board size: 635 X1000 mm

Copper Thickness: 1 oz

Layers: 1-50 layers

Solder mask color: green, yellow, red, black, blue, white

Surface treatment: HASL / ENIG

Why Choose China PCBA Supplier KSPCBA as Your Smart Door Lock PCB Assembly Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108