* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

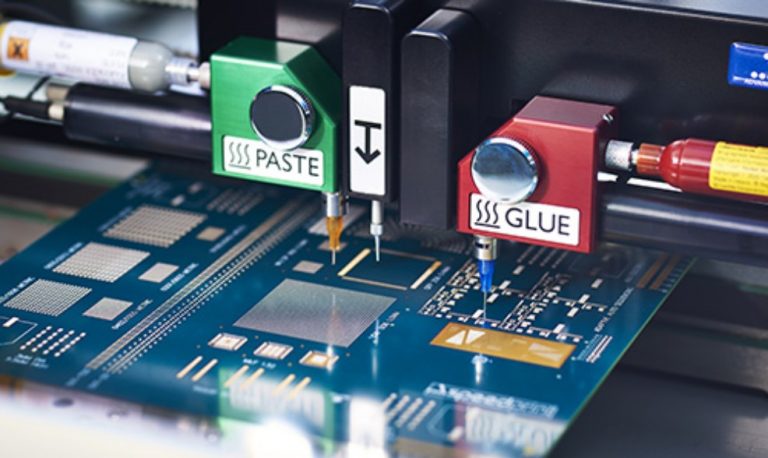

Below are the main development trends in SMT (Surface Mount Technology) assembly and manufacturing processes:

1. Automation Development Trend

SMT products are typically small and require a highly automated, precision manufacturing process for high-speed production. As a result, advanced measurement and control technology is needed to ensure accuracy and efficiency in the assembly process. Traditional quality measurement and control methods like manual visual inspection are no longer suitable for SMT products. Therefore, there is a growing trend towards fully adopting automatic detection methods such as optical automatic detection and computer-aided assembly quality control techniques to ensure high-quality SMT assembly.

2. Intelligent Development Trend

The miniaturization and high density of SMT products, along with their automated assembly processes, generate complex quality inspection and control data that cannot be effectively managed using traditional manual methods. As a solution, there is a shift towards automated testing and intelligent control technology to collect, analyze, and diagnose quality information. This trend aims to replace manual quality control with intelligent quality measurement and control technology for SMT assembly.

SMT Assembly Quality Measurement And Control Technology

3. Integrated Development Trend

SMT product assembly is a comprehensive system that involves various aspects of manufacturing, design, supply chain, and management. Therefore, there is a growing emphasis on integrating quality inspection and control into the overall system. This involves coordinating raw materials, assembly equipment performance, reliability design, and quality assurance systems to enhance SMT product quality control and address quality issues proactively.

4. Forward Development Trend

The focus of quality inspection and control in SMT assembly has shifted from traditional product terminals to various processes within the assembly process itself. The aim is to address quality issues within the process to reduce costs and quality risks, ultimately aiming for high first-pass assembly rates. With the advancement of detection and control technology, SMT assembly systems can now perform real-time quality inspection and feedback, leading to more efficient and high-quality production.

Why Choose China PCBA Supplier KSPCBA as Your SMT Assembly Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108Online Service