* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

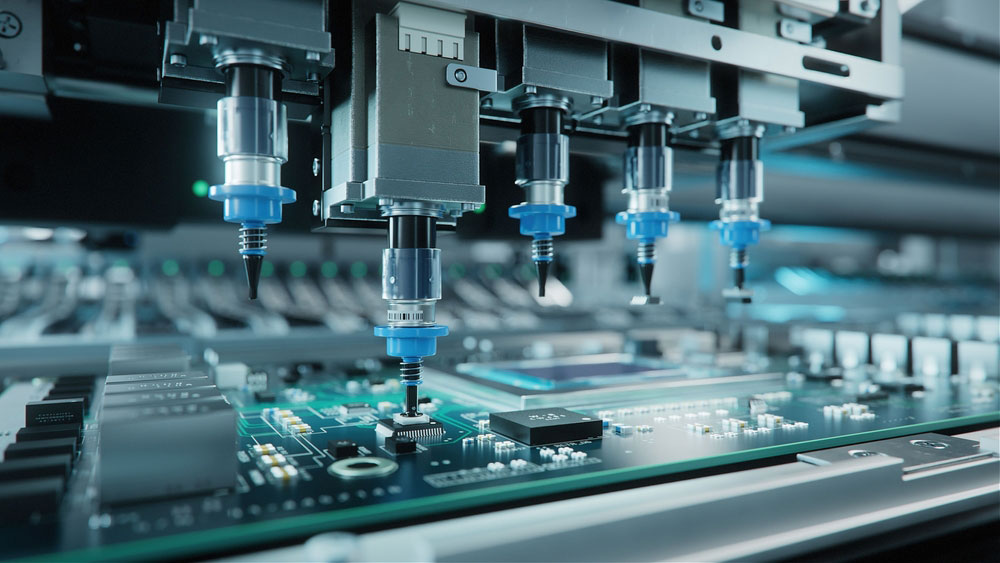

SMT Technology Overview

SMT (Surface Mount Technology) involves mounting and soldering chip components on the surface of a printed circuit board. Compared to traditional through-hole assembly methods, SMT offers numerous advantages, including higher assembly density, reduced product size (with volume reductions of 40% to 60%), lighter weight (weight reductions of 60% to 80%), increased reliability, enhanced vibration resistance, and ease of automation.

Currently, over 80% of electronic products in developed countries like Japan and the United States utilize SMT. The primary application areas include network communications, computers, and consumer electronics, accounting for approximately 35%, 28%, and 28% of the market, respectively. Other applications include automotive electronics and medical electronics.

SMT Production Line Components

An SMT production line comprises various crucial pieces of equipment, including:

- SMT machine

- Printing machine

- SPI (solder paste inspection) machine

- Wave soldering equipment

- Reflow soldering equipment

- AOI (Automated Optical Inspection) testing equipment

- X-ray testing equipment

- Repair workstation

The technologies involved in SMT include mounting technology, soldering technology, semiconductor packaging technology, assembly equipment design technology, circuit formation technology, and function design simulation technology.

Among these, the SMT machine is essential for achieving high-speed, high-precision automatic placement of components. The efficiency and accuracy of the SMT production line heavily rely on this equipment, which typically accounts for more than 60% of the total investment in the SMT production process. The evolution of placement machines has progressed from early low-speed mechanical machines to high-speed optical alignment machines, and now includes multifunctional, flexible, and modular designs.

SMT Electronic Manufacturing Equipment Automation Analysis

Market Landscape

In the domestic market, leading enterprises have emerged in the printing, welding, testing, and related fields. Notable examples include Nitto, Jingtuo (welding equipment), Kegg (printing presses), and Shenzhou Vision (AOI and X-ray testing equipment). However, the core technology for SMT machines remains dominated by manufacturers from Japan, Germany, South Korea, and the United States, with key players such as ASMPT (which acquired Siemens' SIPLACE mounting equipment division in 2011), Panasonic, Global, Fuji, Yamaha, JUKI, and Samsung.

Driving Forces for Change

The ongoing technological revolution and new demands for economic and social development are leading to significant changes in market dynamics. Concepts such as transformation, upgrading, and the integration of technologies reflect these shifts in demand. Reducing labor costs while enhancing automation levels is essential for the technological transformation and upgrading of manufacturing processes. This creates a strong demand for SMT equipment.

On one hand, these changes impose higher requirements for production complexity, accuracy, processes, and specifications. On the other hand, increasing labor costs challenge companies to balance cost-efficiency. Consequently, there is a growing need for automated, intelligent, and flexible production systems, processing, assembly, installation, packaging, and testing.

For instance, Sichuan Changhong has planned to enhance automation levels through technological advancements, aiming to decrease costs and maintain competitiveness by reducing labor costs by 20% over two years and 50% over four years.

Future Trends

As competition in the electronics industry intensifies, companies must adapt to shorter time-to-market cycles for new products, comply with stricter environmental requirements for cleaning and lead-free solder applications, and stay aligned with trends toward lower costs and miniaturization. These factors raise the bar for electronic manufacturing equipment.

Electronic equipment is evolving toward higher precision, increased speed, enhanced usability, greater environmental sustainability, and more flexible production lines. The SMT machine's high-speed and multifunction heads can be interchanged seamlessly, and the adhesive head can be swapped out for a dispensing head, transforming it into a dispensing machine. This results in improved stability in printing and mounting accuracy, as well as greater flexibility in accommodating changing components and substrates.

Why Choose China PCBA Supplier KSPCBA as Your SMT Electronic Manufacturing Equipment Automation Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108