* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

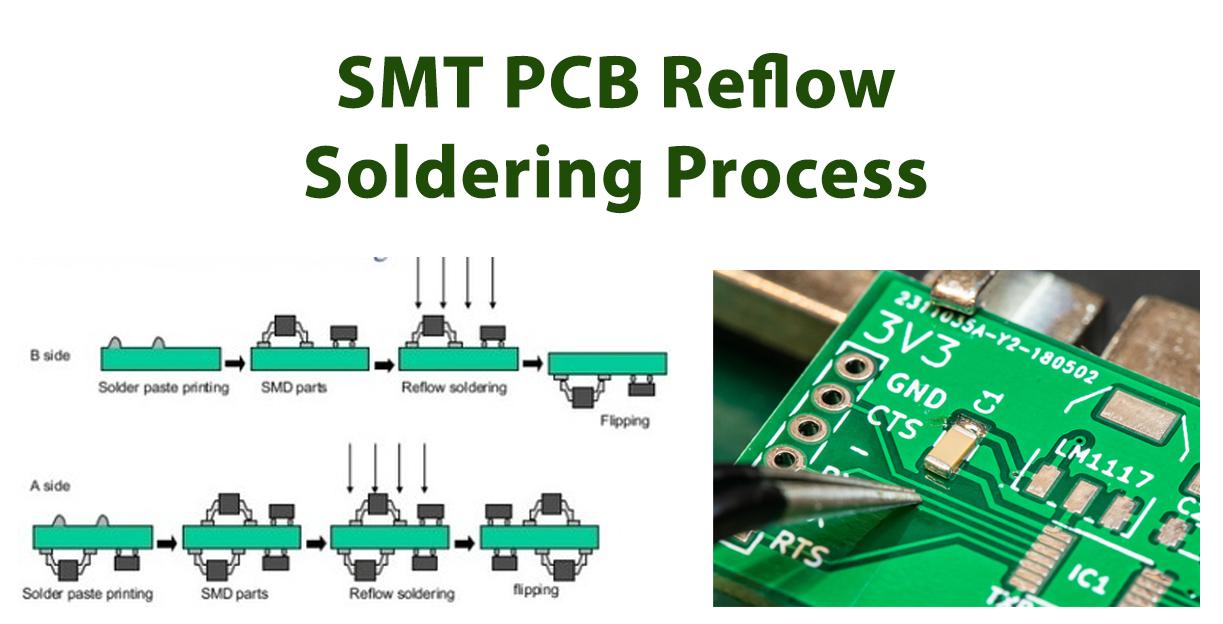

Surface Mount Technology (SMT) is a key contributor to the thriving electronics industry. Reflow soldering, a crucial SMT technique, involves technical aspects and specific temperature settings.

Reflow soldering for printed circuit board assembly typically involves four main phases: Pre-heat, Soak, Reflow, and Cooling. It's important to adhere to the profile requirements specified by solder paste manufacturers due to ongoing advancements in solder paste and flux formulations.

After the reflow process, the cooling zone aids in solidifying the solder joints for subsequent assembly processes. Controlling the cooling rate is crucial to prevent damage to the joints.

SMT Reflow Soldering And Process Attention Points

The cooling zone should rapidly decrease the temperature to solidify the solder. Rapid cooling can lead to stronger, shinier solder joints, although voids may form due to insufficient gas escape time. Conversely, slow cooling can lead to the formation of excessive intermetallic compounds and larger crystal grains.

Faster cooling effectively reduces the formation of intermetallic compounds. However, care should be taken to ensure that the part's impact resistance is not compromised. It's important to note that capacitors have a maximum allowable cooling rate of about 4°C/sec and the recommended cooling rate generally falls between 2-5°C/s.

Additionally, SMT is known for high assembly density, small size, and light weight of electronic products, reduced electromagnetic and radio frequency interference, and improved production efficiency. Reflow soldering should also focus on compatibility with small outline diode (SOD) mounting pads, including pad wettability and SOD heat resistance.

Features of SMT:

- High assembly density, small size, and light weight of electronic products

- High reliability and strong anti-vibration ability

- Good high frequency characteristics, reducing electromagnetic and radio frequency interference

- Easy automation and improved production efficiency, resulting in cost savings of 30%-50% and reduced material, energy, equipment, and labor requirements.

Why Choose China PCBA Supplier KSPCBA as Your SMT Reflow Soldering Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108