* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

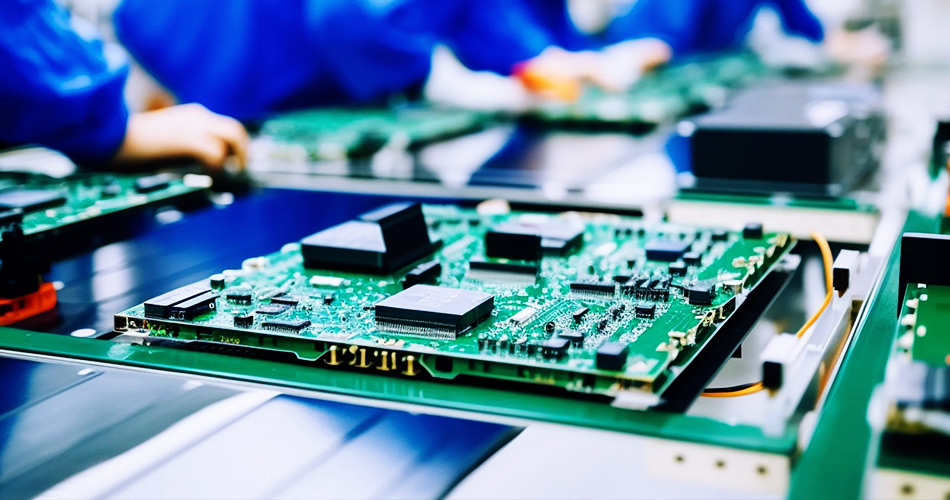

How to Reduce and Eliminate Solder Beads and Dross on PCBA Boards?

During the PCBA (Printed Circuit Board Assembly) processing, factors related to the manufacturing process and manual operations can lead to the occurrence of solder beads and dross on the PCBA board. These issues pose significant risks, as loose solder beads or dross can create short circuits, potentially resulting in product failures. This risk may arise during the product's lifecycle, creating challenges for customer support and after-sales service.

Causes of Solder Beads and Dross on PCBA

1. Excessive Solder on SMD Pads: During the reflow soldering process, too much solder on the Surface-Mount Device (SMD) pads can lead to the extrusion of solder beads from the molten solder.

2. Moisture on PCB or Components: If the PCB or components are not properly dried, moisture can vaporize during reflow soldering, causing solder to splash and form beads on the board's surface.

3. Manual Soldering Issues: During the manual soldering process, when operators add solder, the soldering iron can splash solder beads onto the PCBA.

4. Other Unknown Factors: There may be additional, unspecified reasons for the occurrence of solder beads and dross.

The Basic Cause of PCBA Tin Beads and Slags

Measures to Reduce Solder Beads and Dross on PCBA

1. Stencil Fabrication: Pay close attention to stencil fabrication. Adjust the opening sizes based on the component layout to control the amount of solder paste printed, especially for densely packed components.

2. Moisture Control: For bare PCBs with BGA (Ball Grid Array), QFN (Quad Flat No-lead), and closely spaced components, it is essential to strictly adhere to baking procedures to remove moisture from the pad surfaces. This maximizes solderability and helps eliminate solder beads.

3. Manual Soldering Supervision: When manual soldering is necessary, control the soldering process closely. Designate proper storage for tools and ensure tables are cleaned regularly. Additionally, implement visual inspections of SMD components near manually soldered areas, focusing on any solder joints that may have been accidentally disturbed or on the presence of solder beads and dross between component pins.

Since PCBA boards are precise electronic components sensitive to conductive objects and ESD (Electrostatic Discharge), it is crucial for factory managers to enhance management practices. Strengthening quality awareness among operators and quality assurance teams—through process control and a commitment to mindful practices—is essential to minimizing the production of solder beads and dross on PCBA boards.

Why Choose China PCBA Supplier KSPCBA as Your The Basic Cause of PCBA Tin Beads and Slags Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108