* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

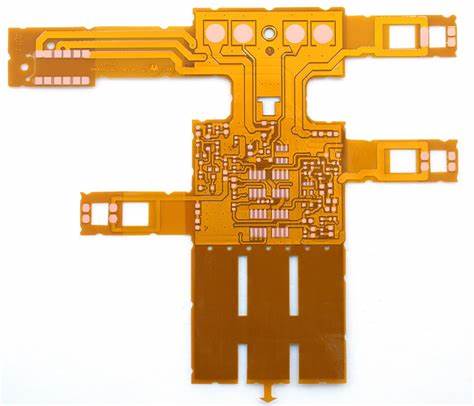

If the circuit board design is relatively simple, the total volume is not large, and the space is suitable, the traditional interconnection method is mostly much cheaper. If the circuit is complex, handles many signals, or has special electrical or mechanical performance requirements, a flexible circuit board is a better design choice. Flexible assembly is economical when the size and performance of the application exceed the capabilities of rigid circuit boards.

A flexible circuit board with 12mil pads with 5mil through holes and 3mil lines and spaces can be made on a single film. Therefore, it is more reliable to mount the chip directly on the film because it does not contain flame retardants that may be a source of ionic contamination. These films may be protective and cure at higher temperatures, resulting in higher glass transition temperatures.

The reason for the cost savings of flexible materials over rigid materials is the elimination of connectors. The high cost of raw materials is the main reason for the high price of flexible circuit boards. The price of raw materials varies greatly. The cost of raw materials used in polyester flexible circuit boards is 1.5 times that of rigid circuit boards; high-performance polyimide flexible circuit boards are as high as 4 times or more.

At the same time, the flexibility of the material makes it difficult to automate processing during the manufacturing process, resulting in lower yields; defects are prone to occur during the assembly process, including peeling off flexible attachments and breaking lines. This type of situation is more likely to happen when the design is not suitable for the application. Under high stresses caused by bending or forming, it is often necessary to select reinforcing or reinforcing materials.

The cost of PCB flexible circuit board

Although the cost of raw materials is high and the manufacturing is troublesome, the foldable, bendable and multi-layer paneling functions will reduce the size of the overall assembly, and the materials used will be reduced, so that the total assembly cost will be reduced.

Generally speaking, PCB flexible circuit boards are indeed more expensive than rigid circuit boards. In the manufacture of flexible boards, many cases have to face the fact that many parameters are out of tolerance. The difficulty in manufacturing flexible circuit boards is the flexibility of the material.

Despite the above-mentioned cost factors, the price of flexible assemblies is falling and is becoming close to that of traditional rigid circuit boards. The main reasons for this are the introduction of newer materials, improved production processes and altered structures. The current structure makes the product more thermally stable, with very few material mismatches. Some newer materials allow for more precise lines due to thinner copper layers, making components lighter and more suitable for fitting into small spaces.

In the past, copper foils were attached to adhesive-coated media using a rolling process. Today, copper foils can be produced directly on the media without the use of adhesives. These techniques can obtain copper layers that are several microns thick, and precise lines with widths of 3 mil or even narrower. The flexible circuit board has flame retardant properties after some adhesives have been removed. This can speed up the UL process and further reduce costs.

Flexible circuit board solder masks and other surface coatings further reduce flexible assembly costs. In the coming years, smaller, more complex and more expensive flexible circuit boards will require newer methods of assembly and the increase of hybrid flexible circuit boards. The challenge for the flexible circuit board industry is to take advantage of its technology to keep pace with computing, telecommunication, consumer demands and dynamic markets. In addition, flexible printed circuit boards will play an important role in the lead-free movement.

Why Choose China PCBA Supplier KSPCBA as Your PCB flexible circuit board Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108