* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

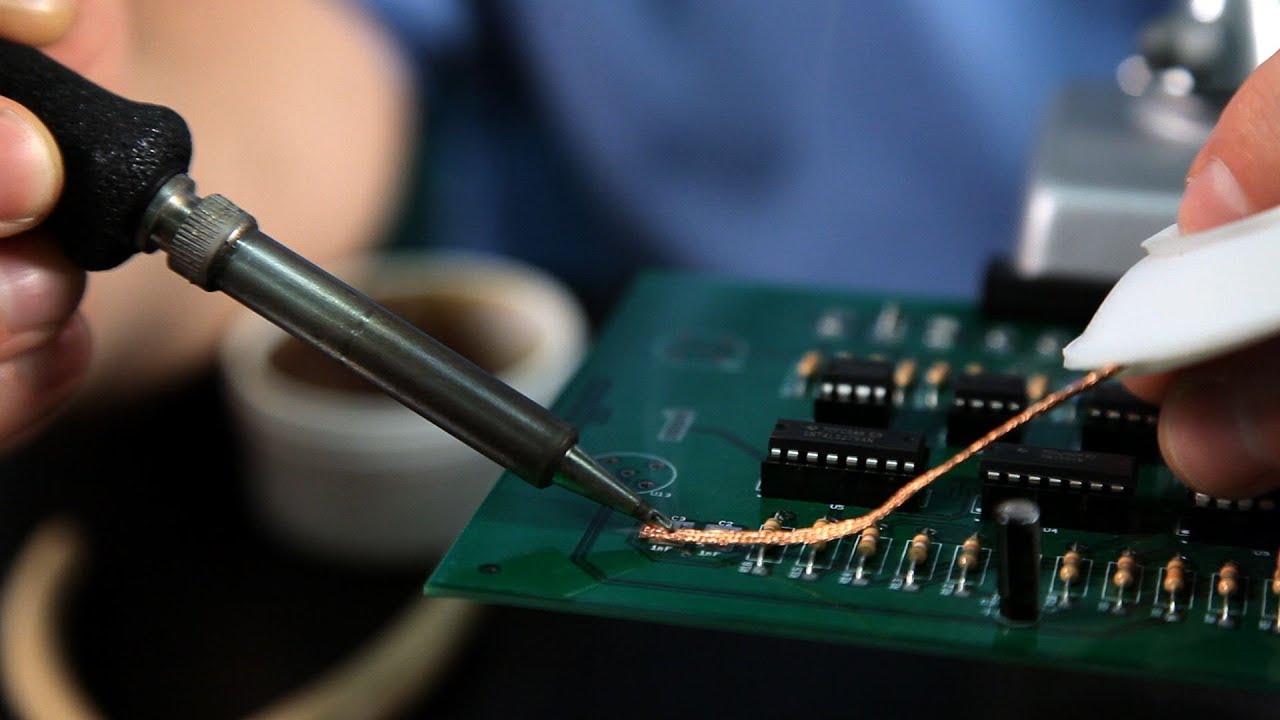

Changing to lead-free has implications for PCB manufacture, assembly, testing, and inspection. However, as far as X-ray inspection is concerned, all that may be necessary is the adjustment of certain X-ray tube parameters to ensure the best image contrast.

Kingsheng PCBA Tech can make BGA assembly, inspection, and repair. With a decade of years experience in the EMS industry, we provide flexible electronic manufacturing service with BGA inspection and repair. We aim to meet customers' satisfaction with the best quality and professional service.

X-rays are commonly used in the electronics industry to inspect solder joints. In 2007, due to environmental concerns regarding the impact of lead waste, the electronics industry decided to reduce or eliminate the use of lead in their manufacturing processes. However, military and aerospace companies have been exempted from this requirement temporarily due to concerns about the reliability of lead-free solders in mission-critical products. As commercially available lead parts become scarce, some aerospace and military companies are now considering the use of lead-free parts.

Many countries worldwide are quickly taking steps to get rid of lead from the manufacturing of electronics. Some companies are using the opportunity to advertise their products as "lead-free" in the consumer market. However, other companies are resisting the shift to lead-free production, despite the global legislation on the matter.

Since RoHS was implemented in 2006, Sn3.0Ag0.5Cu (SAC305) has been the primary lead-free solder used to attach electronic devices to printed circuit boards (PCBs). However, the 3.0 wt% Silver (Ag) in SAC305 makes it expensive, and companies are looking for cheaper alternatives, especially for use in affordable products with short operating lives and mild application conditions. This paper examines new lead-free solder alternatives and industry trends, including SnCu-based solders, SnAgCu solders with Ag content below 1.0 wt%, SnAg solders, and no-Ag low-temperature solders (such as SnBi-based solders). The analysis covers reflow, wave, and rework conditions, as well as packaged and flip-chip devices.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108