* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

A summary of resistor material selection, evaluations and duplication of a complex digital design.

The concept behind embedded passives technology (EPT) is to fabricate and bury components such as resistors and capacitors (R&C) within the layers of a substrate during its fabrication.1 EPT drivers include demand for additional functionality at the same or lower price, better electrical performance, higher packaging density and technologies with potential cost savings. Using EPT, passive components may be embedded into the substrate directly under active devices such as ASICs. The shorter distance between the embedded passives and active components reduces parasitic losses associated with surface-mounted passives, resulting in better signal transmission and less crosstalk. Lower loss and lower noise yield an improvement in electrical signal performance, especially at high frequencies. Passive components account for 80 to 95% of the total number of components and cover over 40% of the surface of the PCB.

Reducing the number of surface mount passives will increase available real estate and therefore permit higher packaging densities. It has the potential to reduce material costs due to fewer purchased components and manufacturing materials (flux and solder), lower defect per million opportunities (DPMO), improve yield, and reduce production cycle time and time to market, as well as reduce cost of poor quality (COPQ). EPT can simplify assembly and test processes and reduce the actual cost, especially when using 0201 packages or lead-free processes. EPT reduces overall product cost in comparison with traditional use of discrete SMT components.

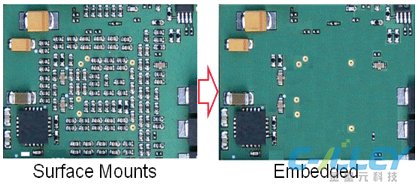

Design and functionality. Customer demands for increased functionality for aerospace applications have resulted in high-density PCB designs that are low yield and high complexity, DfM violations, and significant hidden factory rework during assembly. EPT provides a means to reduce the number of surface-mounted components, thus increasing yields and freeing real estate (FIGURE 1). Although capacitors, resistors and inductors are all candidates for embedding, most current interests focus on capacitors and resistors since they represent the majority of passives used on a board. A generic single board is generally composed of 5% integrated circuits (ASICs), 4% connectors, 40% capacitors, 33% resistors and 18% miscellaneous parts.2 Embedded resistors and capacitors can be individually fabricated, and capacitors can also be manufactured in distributed planar form.

Figure 1 . Surface mount assembly vs. embedded technology(Good for rework of BGA Assembly)

Summary

Embedded passive technology is viable and has been reliably used in the defense and aerospace industry for over 20 years. EPT’s value is creating space on a crowded PCB where more active components are needed. Embedding resistors and capacitors can increase board functionality without increasing board size. It improves signal performance and reduces parasitics and crosstalk. EPT can increase reliability by eliminating surface mount devices and the defects associated with assembly processes such as placement and soldering.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108