* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

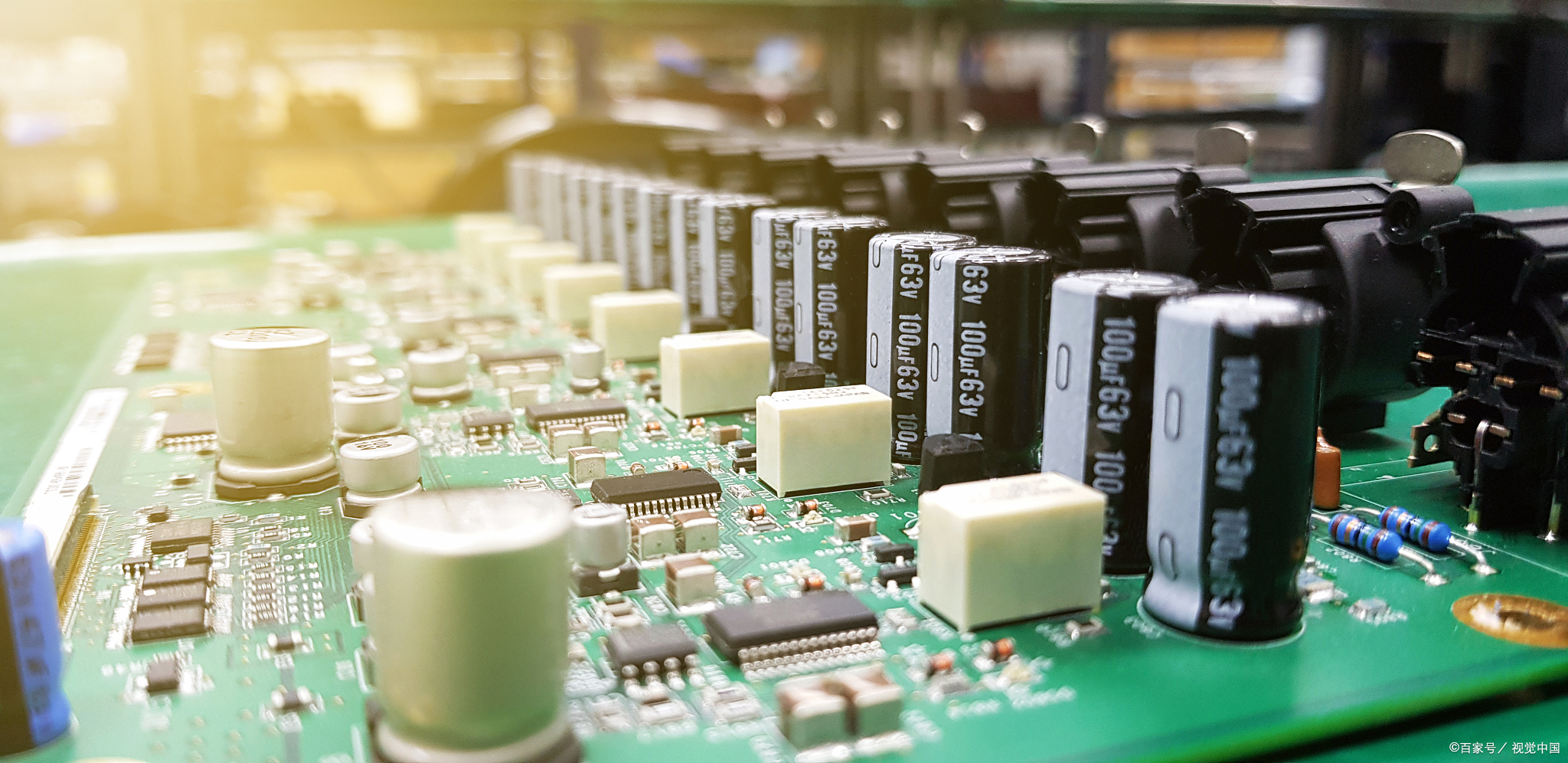

Shenzhen Kingsheng PCBA Tech Co.,LTD share with you PCB industrial report...

The report highlights the rigid PCB. In 2011, the output value of PCB, a full-blown industry, grew by 23.8%, a record high since 1998. In 2012, the growth in output value slowed down to only 5.9%. And the figure in 2013 is expected to further trend down to roughly 4%.

PCB industry has its unique characteristics. Firstly, it requires demanding environmental-friendly standard and enterprises concerned are obliged to obtain pollution discharge permit from the government; secondly, as a energy-intensive industry, sufficient and steady water and power supply must be ensured; thirdly, it’s a capital-intensive industry that involves chemical engineering, machinery and electronics technologies, and a large number of skilled talents are in need. Therefore, it is difficult for PCB companies to relocate for sustained and long-term development.

Since H12010, the smart phone shipment has seen sharp increase, resulting in the strong demand for HDI applied in smart phones. In H2 2010, leading PCB manufacturers expanded their HDI capacities, but in Q4 2011, HDI experienced oversupply, pulling down capacity utilization. The production capacity of HDI concentrates in Taiwanese businesses. In 2011, the Taiwan dollar appreciated against the US dollar and the Taiwan-based PCB manufacturers witnessed handsome growth in revenue if calculated by the US dollar, while a meager increase if calculated by the Taiwan dollar.

The PCB applied in iPhone, Anylayer model, is the most advanced among PCB products and the major suppliers are Taiwanese businesses. Apple has a large number of rigid PCB suppliers, including Japan-based Panasonic, Ibiden and MEIKO, Taiwan-based Tripod, Unmicron, Compeq, America-based Multek and Austria-based AT&S. For Taiwan-based manufacturers, they provide close to 60% PCB products for Apple.

In 2011, a big change in PCB industry was the capacity transferred to Chinese Mainland centering in Hubei and Chongqing. The investment in Hubei included: the third batch of investment in Wuhan by Japan-based MEIKO, the investment in Wuhan by Beijing-based KDS, the investment in Xiantao by Tripod Technology Corporation and the investment in Huangshi by WUS Printed Circuit. And investors in Chongqing included: GBM, AT&S and HannStar Board. In addition, there were Huatao Electronics which invested in Suining of Sichuan, Taiwan PCB Techvest which invested in Chengdu and, Trendtronics and Huaxiang Circuit which invested in Jiujiang of Jiangxi.

Still, Yangtze River Delta is the first choice of PCB industry. New PCB entrants are piling into Kunshan and Wuxi markets, while the time-honored players are still on regular operation. Generally speaking, the PCB businesses to establish branches in Mainland China takes strategic development into account, and their main playing ground is still in Yangtze River Delta.

For PCB manufacturers, the traditional PCB products even Anylayer HDI which have seen tough competition and downward gross margin. Relatively, IC substrate features the highest gross margin among all the PCB products. In 2002, IC substrates made a success in mass production by a Japanese enterprise thanks to the assistance from Intel. The IC with the manufacturing process below 50nm requires using substrate, which originally found limited application in CPU, Graphics and Chipset. The boom of mobile phone industry presses the massive application of IC substrate in mobile phone CPU, memory and application processor. In the 4G era, IC substrate gets applied in almost all CPUs for mobile phones to avoid generating enormous heat.

Apart from mobile phone, other applications of IC substrate include HDTV, MPU of STB, base station and high-speed Networking IC. However, the biggest market of IC substrate lies in PC industry and the market is largely dominated by Japanese corporations. In 2012, the Japan-based NGK withdraw from the market and Taiwan-based Nanya PCB became a substitute. Whereas, the PC field has presented low growth but very high threshold admittance.

The IC substrate is not in blue-sea market any more, and the competition is very fierce. But for PCB leaders who seek for rising revenue, there are no way out but to expand IC substrate business. A case in point is Unimicron, the largest PCB supplier around the globe, which has intensified its investment in IC substrate industry in 2012. In addition, ZDT under Hon Hai also announced to made inroad in the area.

After the withdrawn of NGK, only 2 Japanese corporations left-Ibiden and Shinko. With high quoted prices, both of them mainly offer products for Intel. Ibiden is establishing its base in the Philippines, in a bid to lower the price. Both Ibiden and Shinko focus on ABF substrate and have no interest in BT substrate in the communication field.

When it comes to the South Korean manufactures, SEMCO involves in the widest range of businesses. On the one hand, it has the VIP customer of Qualcomm; and on the other hand, considerable ICs from its parent company-Samsung Electronics-are needed packaging by substrates. Besides, SEMCO also receives a small amount of orders from Intel or AMD. SIMMTECH is mainly engaged in the packaging of memory substrate. Also, SIMMTECH is a leading memory PCB manufacturer.

Among Taiwanese manufacturers, NANYA takes Intel as its major client, while Kinsus is a PCB supplier for Qualcomm and Broadcom, 90% shipment of which goes to BT substrate. Unimicron is focused on Graphics IC business.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108