* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

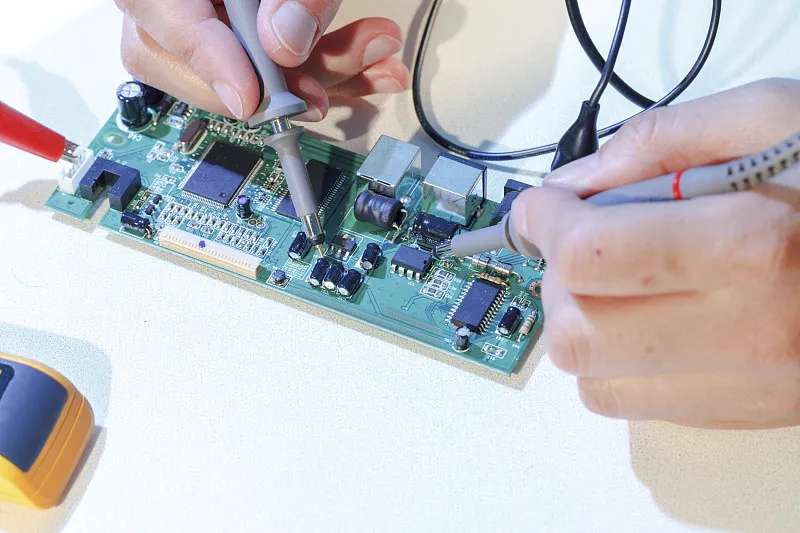

These days, SMT components, such as SMT chips or ICs, are found in a variety of electronic products. Thus, understanding how to take out these SMT components from printed circuit boards or electronic devices is crucial. When SMDs require replacement or maintenance, you must remove them.

An SMT chip can be taken out in a variety of methods. A hot air station may occasionally be able to perform soldering tasks that a soldering iron cannot. Hot air is used by the hot air rework stations to solder or desolder SMT components. In this essay, we'll talk about using hot air to remove an SMT chip.

Within a minute of SMT, removing SMT chip components is a difficult task. To become more proficient at removing components fast and effortlessly without causing damage, you must practice frequently. Please use the steps below simply as a guide:

1. To solder the pins on resistors, capacitors, diodes, transistors, and other pin-less surface mount components, tin plate one of the PCB pads first. Then, using tweezers, put the component in place. Finally, use a soldering iron held in your right hand to solder the pins. Tin wire is used to solder the remaining pins. It's also simple to disassemble these parts: simply heat the assembly's two ends with a soldering iron, then carefully remove it once the tin has melted.

2. The same soldering technique as previously mentioned is used for components with broader SMD pins and wider chip components. Generally speaking, a hot air cannon works better for removing such items. Using tweezers or other clamps, the other hand will remove the assembly once the solder has been melted by the hand-held heat gun.

3. SMT handling in Shenzhen The soldering procedures are the same for a surface mount device with a comparatively high pin density. Soldering the other pins comes after soldering the first pin. The pin and pin alignment are crucial when there are a lot of pins. A hot air cannon is used to remove parts with high densities. After clamping the assembly with tweezers and using a hot air cannon to blast all the pins back, remove the assembly while the pins melt. If the assembly still needs to be disassembled, work quickly and carefully to avoid blowing the assembly center too much. Clean the pads with a soldering iron after removing the components.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108