* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

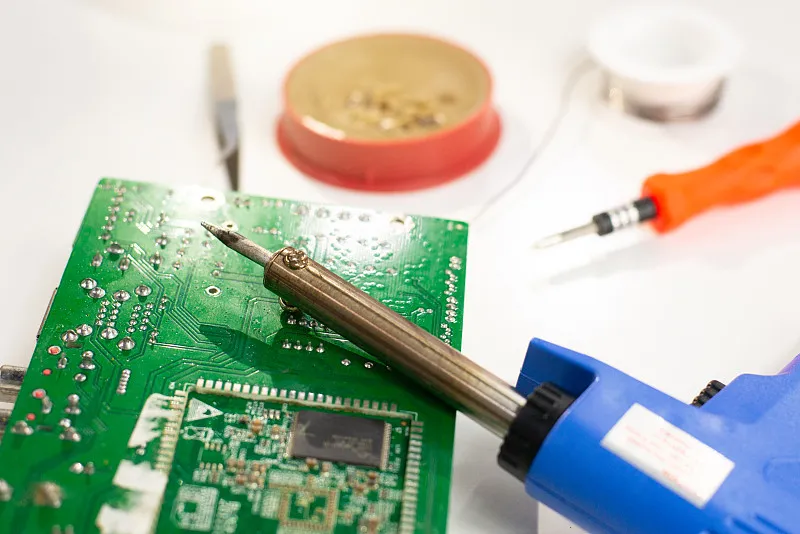

In order to create an electronic assembly, electronic components are soldered to a printed circuit board (PCB) using a small-scale soldering technique called dip soldering. In order to create a sturdy mechanical and electrical connection, the solder wets the exposed metallic portions of the board (those not covered by a solder mask).

Surface mounting and through-hole printed circuit assemblies are both assembled using dip soldering. It is widely utilized in the small-scale industries of underdeveloped nations and is among the least expensive soldering techniques.

The manual counterpart of automated wave soldering is called dip soldering. All that is needed is a little tank filled with molten solder. To get the molten solder to adhere to the exposed metallic parts of a PCB with mounted components, the board must be physically dipped into the tank.

Dip soldering is accomplished by immersing the components to be joined in a molten solder bath.

Therefore, all parts are coated with a filler metal.

Solder has low surface tension and high wetting ability. There are many types of solders, each for different applications.

For example lead-silver, the strength is higher than room temperature. Tin-lead for general purpose;

Tin zinc is used for aluminum; cadmium - silver is used for high temperature strength;

Zinc aluminum for aluminum and corrosion resistance;

Tin - Silver and Tin - for electronic products. Lead-free solders are being developed and are being used more widely due to the toxicity of lead.

The molten bath can be any suitable filler metal, but the choice is generally limited to lower melting elements.

The most common dip soldering operations use zinc aluminum and tin-lead solder.

Solder pot metal - cast iron or steel, electrically heated.

Bath temperature - 220 degrees Celsius to 260 degrees Celsius (binary tin-lead alloy)

Bath temperature - 350 degrees Celsius to 400 degrees Celsius. Celsius (for lead-free alloys)

Solder composition - 60% Sn (tin), 40% Pb (lead) or eutectic alloy.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108