* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

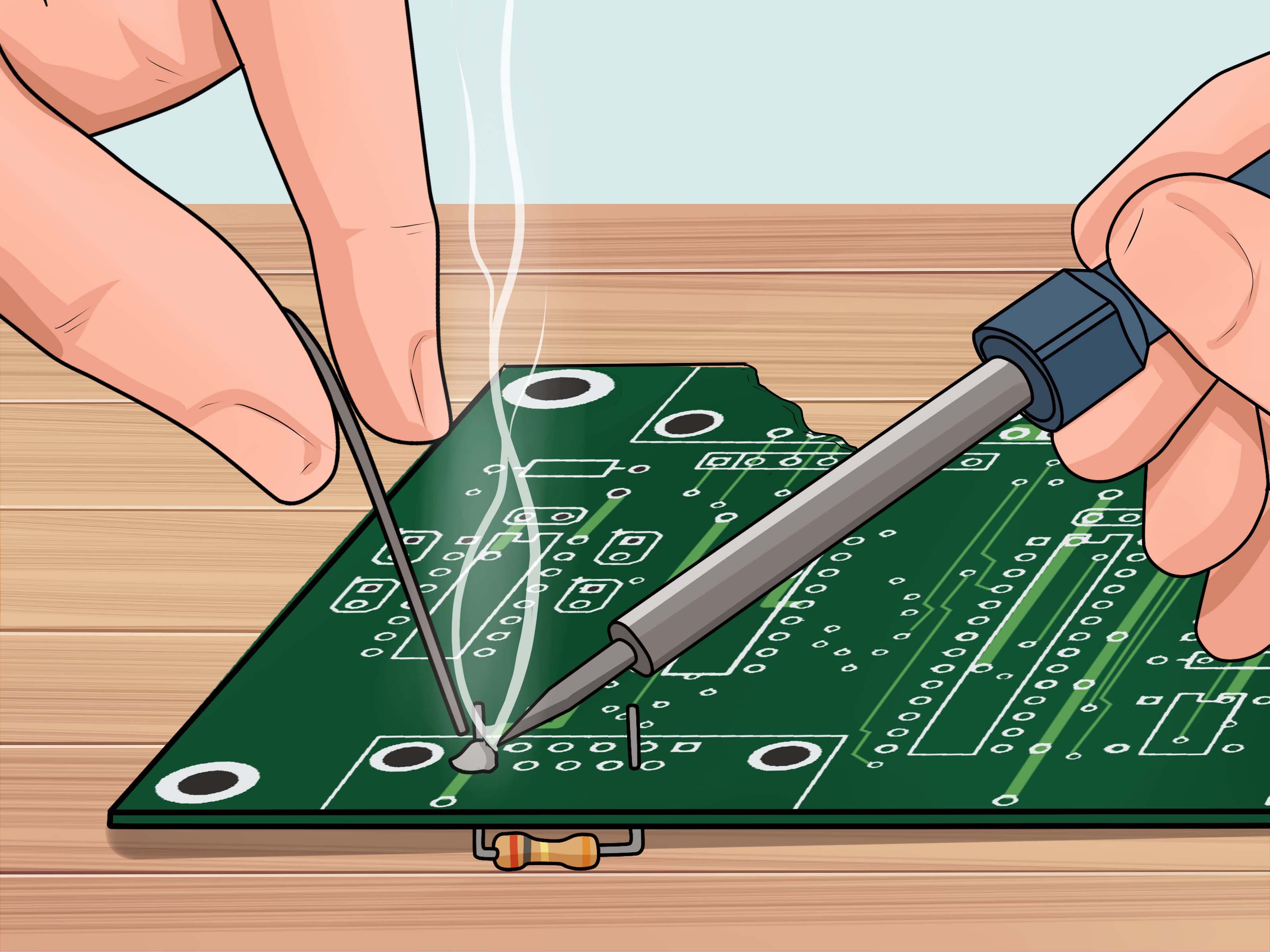

Soldering is one of the most dependable ways to join two metals without melting them, and solder paste is necessary to make this happen. Made up of metal solder particles and a particular blend of flux, solder paste is a unique metal alloy. The unique characteristics of solder paste enable it to melt and create a long-lasting bond during the soldering process, creating a dependable connection between metals.

Solder paste must adhere to a number of critical requirements in order to ensure optimal performance throughout the soldering process. The first need is that it have a low melting point because of the components' temperature sensitivity. Solder paste that has a melting point that is too high runs the danger of melting the components below their maximum temperature threshold before they completely melt. Second, as solder paste is used to make electrical connections as well as mechanical ones, its conductivity is essential for maintaining the continuous flow of electrical current to the components. Finally, the RoHS directive's stringent standards for solder paste raw materials must be met in order to guarantee environmental and human safety.

Lead and tin combined made up around 40% of solder pastes used in electronic manufacture in the past. However, the electronic manufacturing sector has steadily moved to lead-free processes due to the environmental risks connected with lead, as well as technological developments and heightened environmental awareness. Lead-free solder paste has thus gained popularity, demonstrating a constructive reaction to environmental issues and the industry's emphasis on sustainability and health.

1.Steel mesh

The opening of the stencil must be appropriately enlarged or reduced according to the layout of the electronic components on the PCBA board to determine the amount of tin on the pad, so as to achieve the best soldering effect and avoid the occurrence of tin connection and less tin, which requires craftsmanship The engineer conducts a rigorous evaluation. In addition, the material of the steel mesh is also critical.

2.Solder paste

Solder paste needs to use mid-to-high-end brands, such as Senju and Vitero. The solder paste must be stored strictly in a refrigerator at 2 to 10 degrees Celsius.

3.Solder paste printing

At present, manufacturers are using fully automatic solder paste printers, whose equipment can well control the printing strength and speed and other parameters, and has a certain automatic cleaning function. The operator only needs to set the parameters in strict accordance with the regulations.

4.SPI printing effect detection

After the solder paste printing machine, it is particularly important to configure the SPI solder paste detector, which can effectively detect many defects such as small tin, continuous tin, gap, wire drawing, and offset in the solder paste printing process. So as to maximize the overall welding PPM value.

An essential stage in the PCB construction process is solder paste printing. Defects at this stage will have "knock-on" effects that will manifest throughout the entire process. Therefore, in order to accomplish the best solder paste printing procedure, every aspect of the above-described process needs to be examined. A coalescence test can be used to assess the quality of solder paste. The results of this test can also be used to assess the potential effects of ambient temperature and relative humidity on worker performance.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108